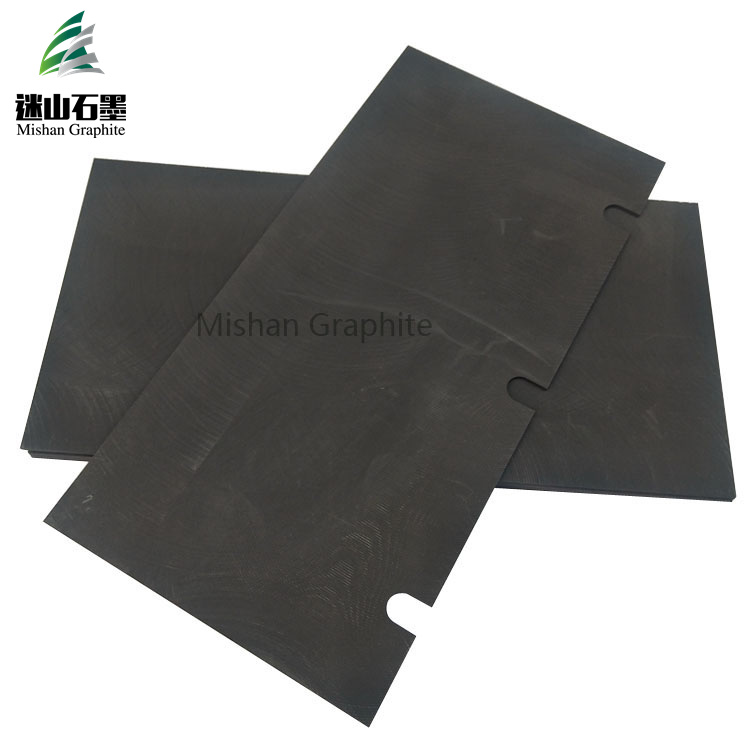

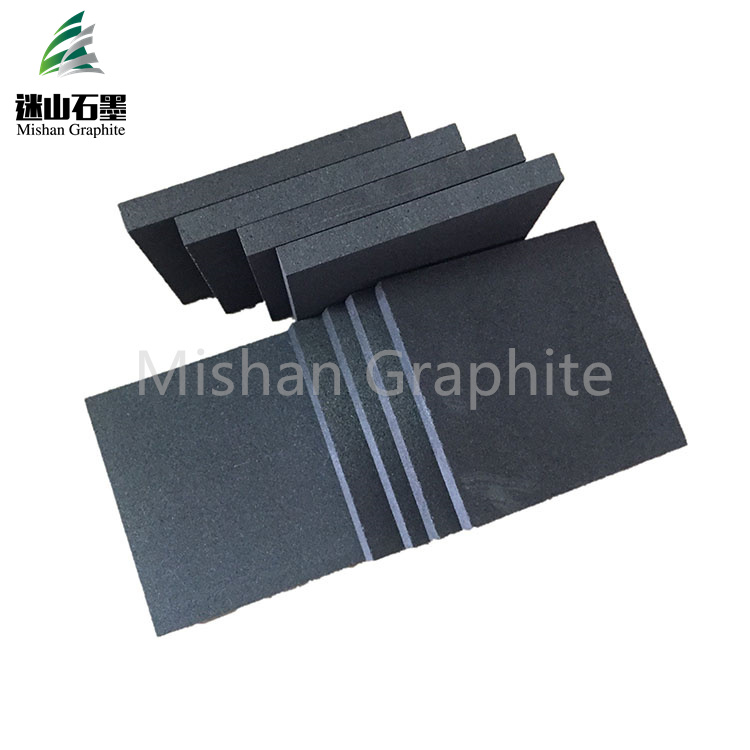

Carbon graphite bipolar plate

In recent years, fuel cell technology has received widespread attention as a promising solution to global energy and environmental challenges. A fuel cell is an electrochemical device that conv...

Description

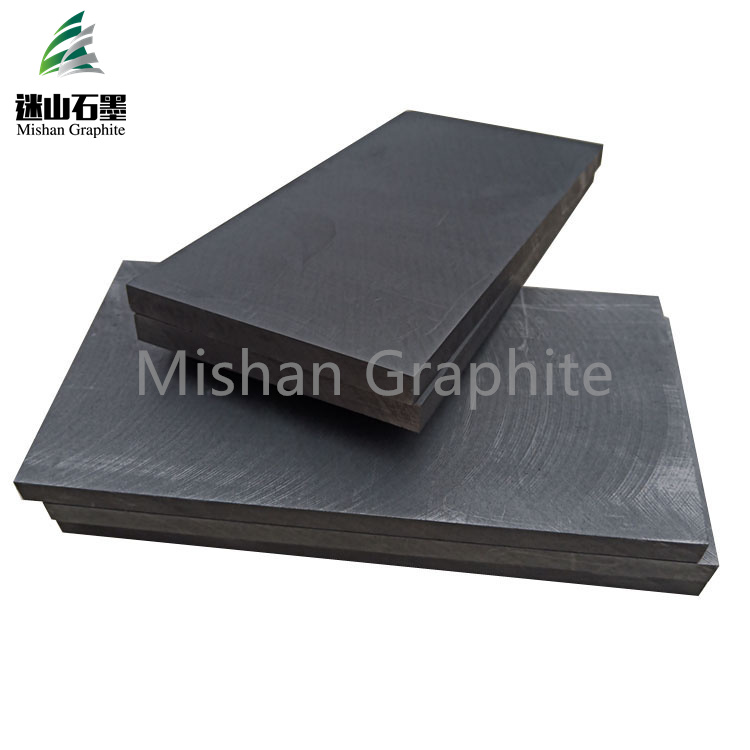

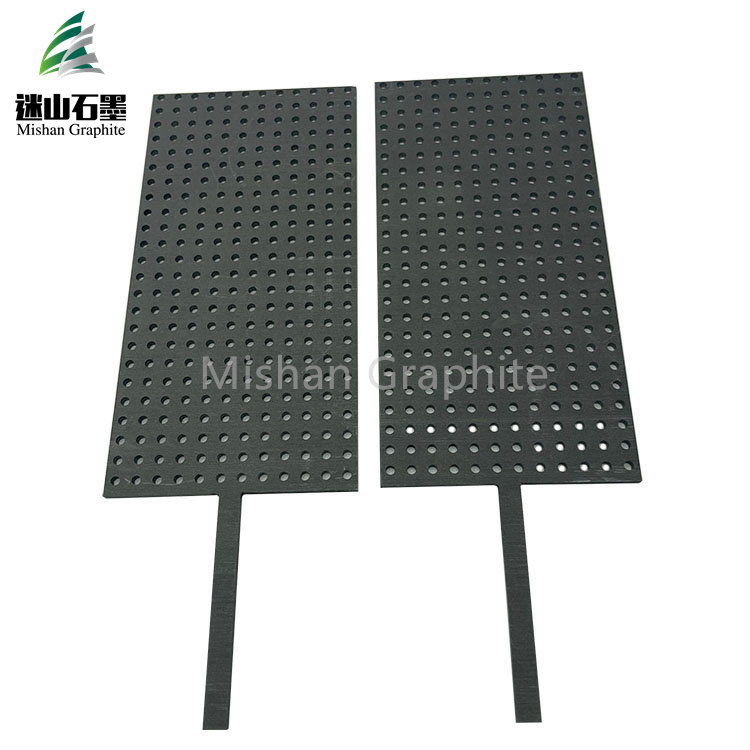

In recent years, fuel cell technology has received widespread attention as a promising solution to global energy and environmental challenges. A fuel cell is an electrochemical device that converts chemical energy stored in a fuel directly into usable electrical energy, with water being the only by-product. Among the key components of the fuel cell stack, bipolar plates distribute reactants, collect electrical current, and provide structural support. Carbon graphite bipolar plate are a popular choice due to their unique properties such as high electrical conductivity, corrosion resistance, high strength-to-weight ratio, and low cost. PACKAGE: DELIVERY TIME:

Let’s take a look at the development trends of carbon graphite bipolar plate:

1. Improve performance and durability:

To achieve better fuel cell performance and reliability, researchers are exploring ways to improve the design and manufacturing of carbon graphite bipolar plate. For example, advanced processing techniques such as laser engraving and ultrasonic processing are used to create precise flow channels for better reactant distribution. Additionally, new materials and coatings are being developed to enhance corrosion resistance and reduce gas penetration.

2. Reduce costs:

As fuel cells move toward commercialization, cost remains a significant challenge. Carbon graphite bipolar plate account for a large portion of the total cost of a fuel cell stack. As a result, researchers are exploring ways to reduce production costs without compromising performance. One way is to use innovative manufacturing methods such as injection molding or compression molding.

3. Integrate with additive manufacturing:

Additive manufacturing, also known as 3D printing, has emerged as a promising technology for rapid prototyping and low-volume production in the fuel cell industry. Carbon graphite bipolar plate can be produced using additive manufacturing techniques, with the potential to reduce costs, increase design flexibility and optimize performance.

4. Application diversity:

Fuel cells are being developed for a variety of applications, from stationary power generation to transportation. Different applications have different requirements for bipolar plates in terms of size, weight, shape and performance. Therefore, researchers are exploring ways to tune the properties of carbon-graphite bipolar plates to meet specific application needs.

In summary, carbon graphite bipolar plate play a vital role in fuel cell technology, and their development has great potential to advance the use of clean energy. As research and development continues, we expect to see further innovations in the design, manufacturing and integration of these panels, leading to improved performance, improved durability, lower costs and new applications.

Veneer cases or wooden cases or according to customers’ requirement.

3-20 days after confirming order,detail delivery date should be decided according to

production season and order quantity.