Characteristics of graphite mold

Graphite molds have become increasingly popular in modern manufacturing processes due to their unique properties and characteristics. In this article, we will discuss the key characteristics of gra...

Description

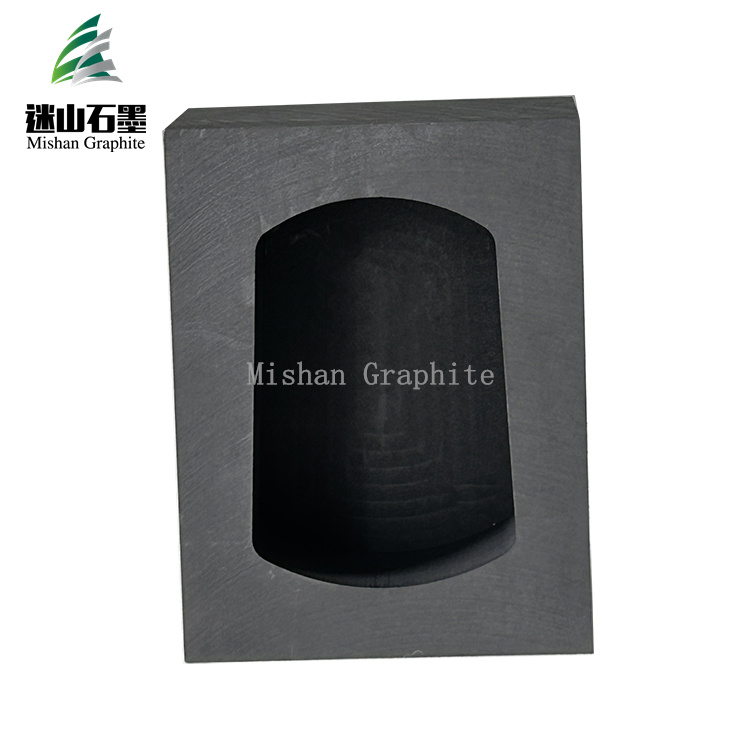

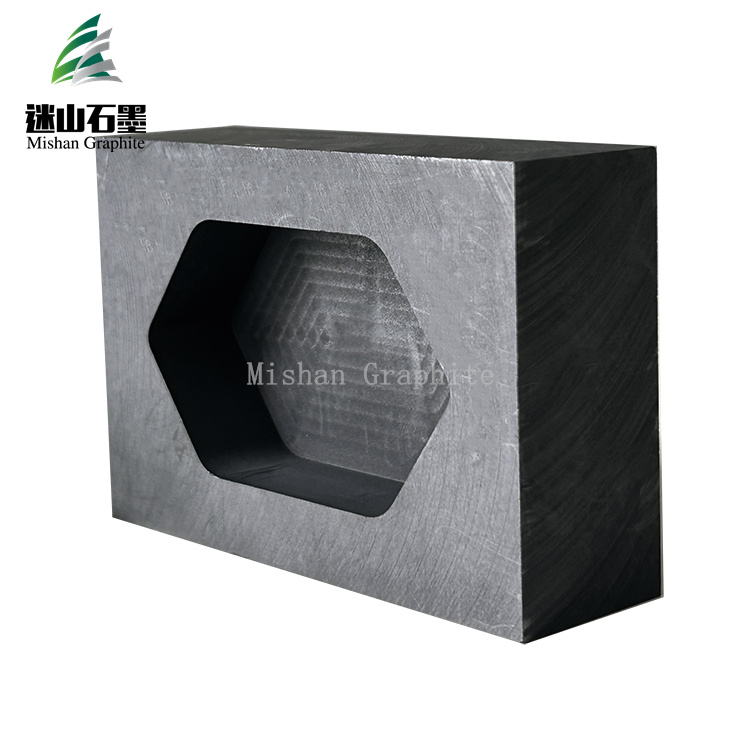

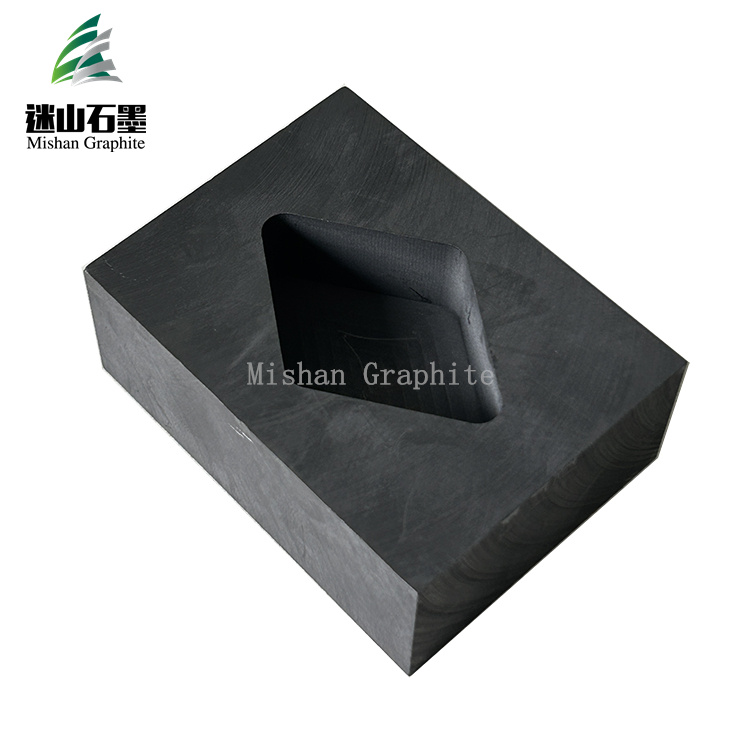

Graphite molds have become increasingly popular in modern manufacturing processes due to their unique properties and characteristics. In this article, we will discuss the key characteristics of graphite molds and their significance in the manufacturing industry. 1. High-density and Hardness: 2. Exceptional thermal stability: 3. Low Coefficient of Thermal Expansion (CTE): 4. Chemical Resistance: 5. Versatility and Reusability: In conclusion, the above-mentioned characteristics of graphite molds make them an essential tool for manufacturing processes that require high precision and complex shapes. They offer manufacturers cost-effective solutions that increase production efficiency and improve the quality of products. Graphite molds are poised to play an increasingly vital role in modern manufacturing as the demand for high-precision components and parts continues to increase.

Graphite molds are known for their high density and hardness, which makes them ideal for producing parts with complex geometries and intricate details. These mechanical properties of graphite molds also make them capable of enduring significant amounts of heat and pressure without getting damaged.

Graphite molds exhibit excellent thermal stability and can withstand relatively high temperatures, making them suitable for use in the casting of high-temperature metals like stainless steel and aluminum alloys. The good thermal stability of graphite molds ensures that they can maintain their shape and size, resulting in consistent part quality during repeatable manufacturing processes.

Graphite molds have a very low CTE, which means they hardly expand or contract under varying temperatures. This property makes them ideal for creating parts that require strict dimensional control, including pressure vessels, aerospace components, and electrical contacts.

Graphite molds are highly resistant to corrosion, oxidation, and chemical reactions, making them suitable for use in the manufacturing of parts and components that will be exposed to harsh chemical environments. The excellent chemical resistance of graphite molds also extends their lifespan, making them cost-effective for manufacturing processes that involve corrosive materials.

One of the significant advantages of graphite molds is their versatility and reusability. Engineers can design graphite molds to produce a broad range of complex shapes, sizes, and geometries cost-effectively. Moreover, graphite molds can be reused multiple times without any significant reduction in their quality, making them an essential tool for manufacturers looking to reduce costs and increase production efficiency.

Send Inquiry

You Might Also Like

- * no