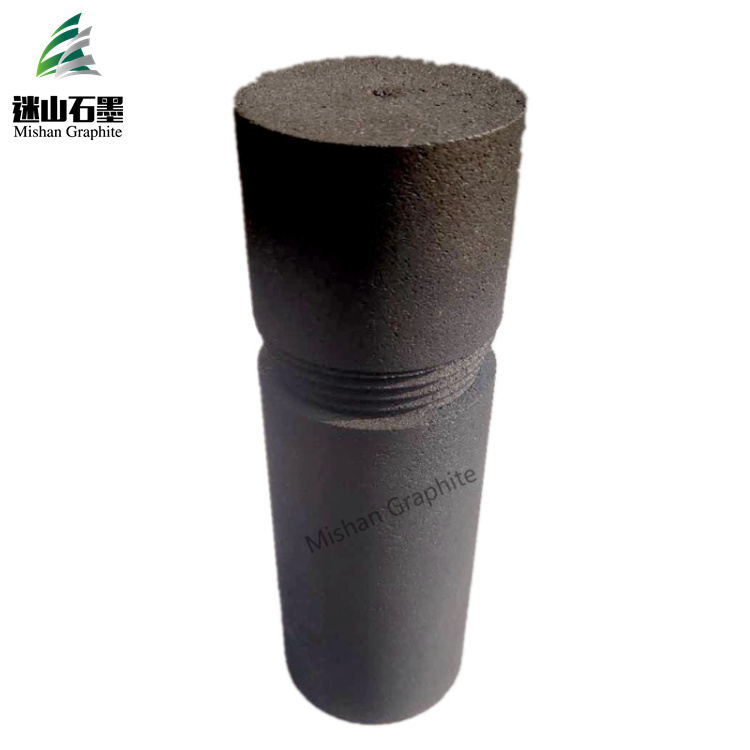

Gold smelting graphite rod

Gold smelting graphite rod is a rod-shaped graphite product processed from high-quality graphite raw materials and has many high-quality properties. As an excellent thermal conductor, graphite ...

Description

Gold smelting graphite rod is a rod-shaped graphite product processed from high-quality graphite raw materials and has many high-quality properties. As an excellent thermal conductor, graphite rods are not easy to melt and deform in high temperature applications, making them very suitable for gold smelting. There is also the fact that graphite rods are not chemically reactive to most substances, which means that graphite rods will not react chemically with molten gold or other metals. PACKAGE: DELIVERY TIME:

So what are graphite rods mainly used for in gold smelting?

During the gold refining process, graphite rods are used to hold gold and other metals in place as they melt. The rod is usually placed in a furnace or kiln and heated until it reaches a high enough temperature to melt the metal. After the metal is melted, graphite rods are used to stir the molten metal and ensure it melts evenly.

The reason why graphite rods are chosen as metal smelting tools is because they have the following advantages:

The main advantage of using graphite rods to smelt gold is its ability to withstand high temperatures. Other materials, such as steel or ceramics, may not be able to withstand the heat required to smelt gold. Graphite also has a very low coefficient of thermal expansion, which means it will not crack or deform when exposed to extreme temperatures.

In addition to its heat-resistant properties, graphite also has low thermal conductivity. This means it does not transfer heat as quickly as other materials, making it ideal for use in gold smelting where temperatures need to be carefully controlled. Graphite’s low thermal conductivity also means it can be used to hold molten metal for longer periods of time without cooling.

To sum up, alchemical graphite rods play a vital role in the gold refining process. Its unique properties make it ideal for use in gold smelting, as it can withstand high temperatures, does not react with most chemicals, and has a low thermal conductivity. The use of graphite rods in the gold smelting process allows for a consistent, efficient melting process, resulting in a high-quality gold product.

Veneer cases or wooden cases or according to customers’ requirement.

3-20 days after confirming order,detail delivery date should be decided according to

production season and order quantity.