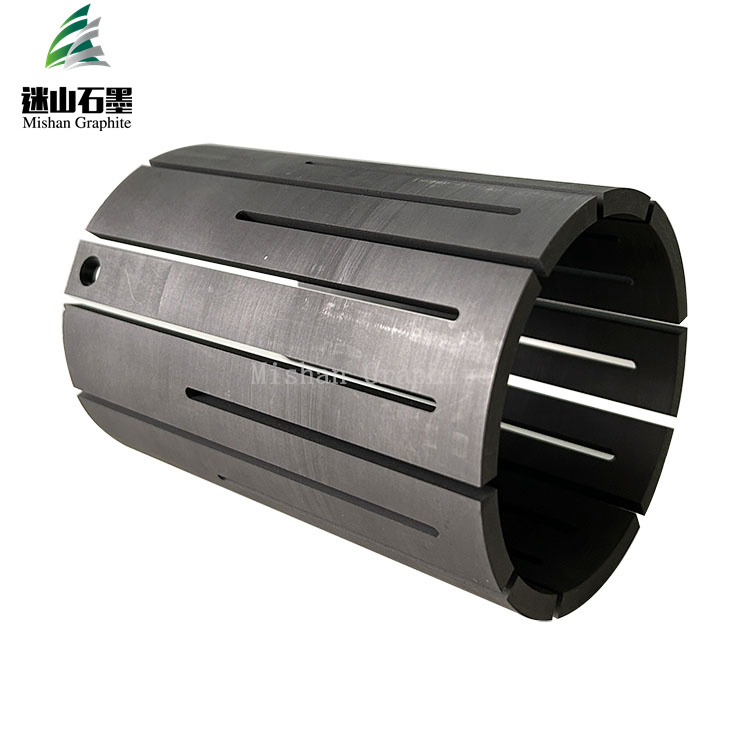

Graphite heater for furnace

Graphite heaters are widely used in industrial furnaces because of their excellent thermal conductivity and high temperature resistance. These heaters are commonly used in heat treatment proces...

Description

Graphite heaters are widely used in industrial furnaces because of their excellent thermal conductivity and high temperature resistance. These heaters are commonly used in heat treatment processes of various metals and alloys as they provide precise and controlled heating for consistent results. PACKAGE: DELIVERY TIME:

In furnace applications, graphite heaters are used as radiant heat sources. The heaters are mounted on the furnace walls, and the radiant heat they emit is absorbed by the workpiece and then heated to the required temperature. The process is commonly used for annealing, tempering and hardening of metals, as well as other heat treatment processes that require controlled temperature and precise heat distribution.

One of the main advantages of graphite heaters is their ability to provide even heat distribution throughout the furnace. This is achieved through the design of the heater, which consists of a series of interconnected graphite elements. These elements are arranged in a specific pattern so that heat is evenly distributed throughout the furnace. This is important during heat treatment as it ensures that the workpiece is heated evenly, resulting in consistent results.

Another advantage of graphite heaters is their ability to withstand high temperatures and harsh conditions. Graphite heaters are made of high-quality graphite, which has excellent thermal performance and high resistance to oxidation and corrosion. This makes them ideal for use in challenging environments, such as high-temperature furnaces that require long periods of operation.

In addition to their thermal performance, graphite heaters are also known for their energy efficiency. Graphite heaters require less energy to operate than other types of heaters, making them ideal for industrial applications that require large amounts of heat. This not only reduces energy costs but also helps minimize the environmental impact of industrial processes.

Overall, graphite heaters are an important part of industrial furnaces used in heat treatment processes. They provide precise and controlled heating, ensuring consistent results, while also providing high temperature resistance, energy efficiency and even heat distribution. When designing and operating an industrial furnace, it is important to select the correct type of heater that meets the requirements of your specific application. Graphite heaters have many advantages and are an excellent choice for this purpose.

Veneer cases or wooden cases or according to customers’ requirement.

3-20 days after confirming order,detail delivery date should be decided according to

production season and order quantity.