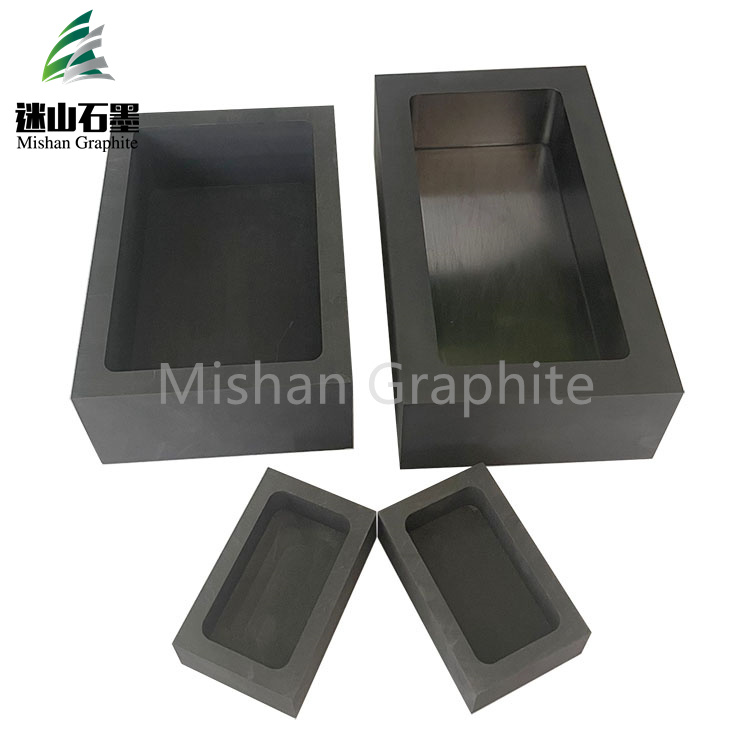

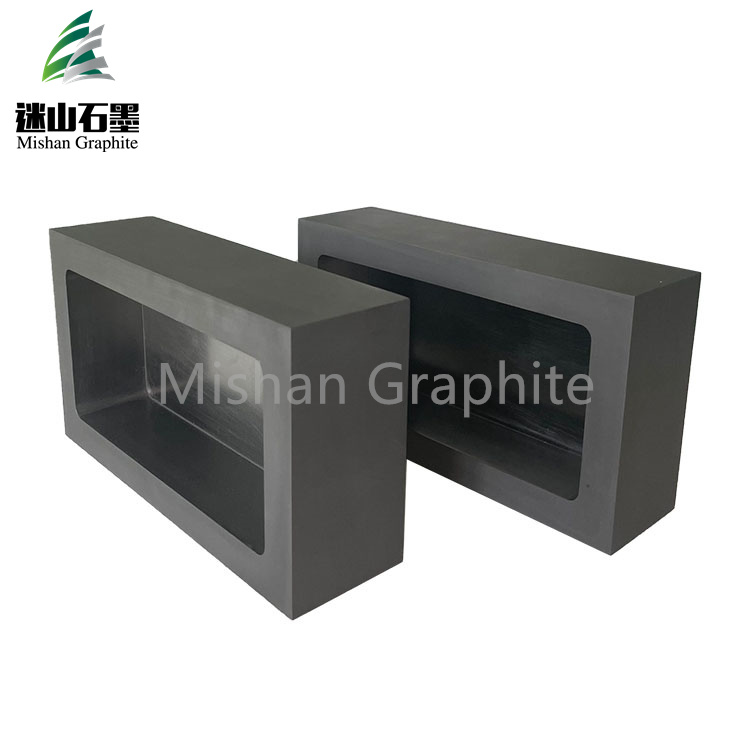

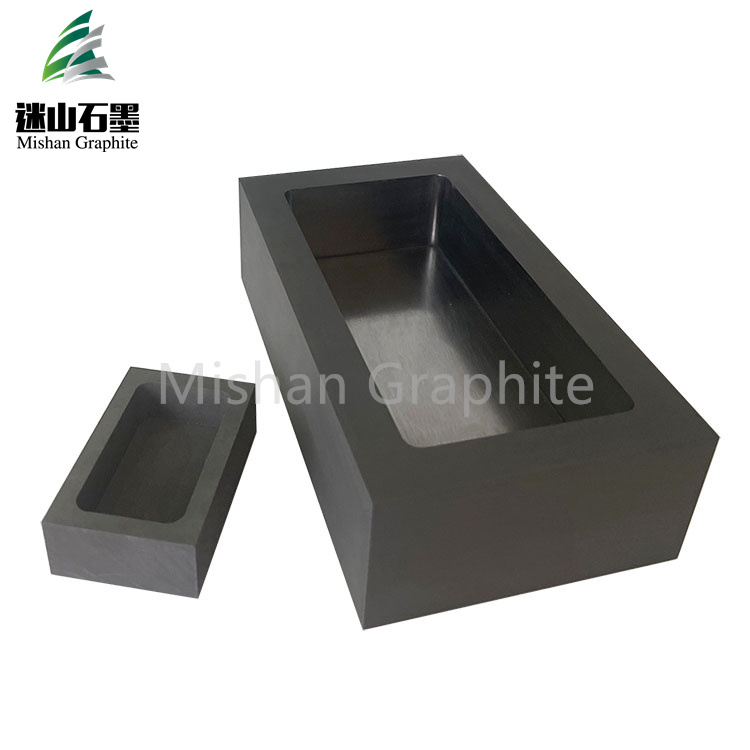

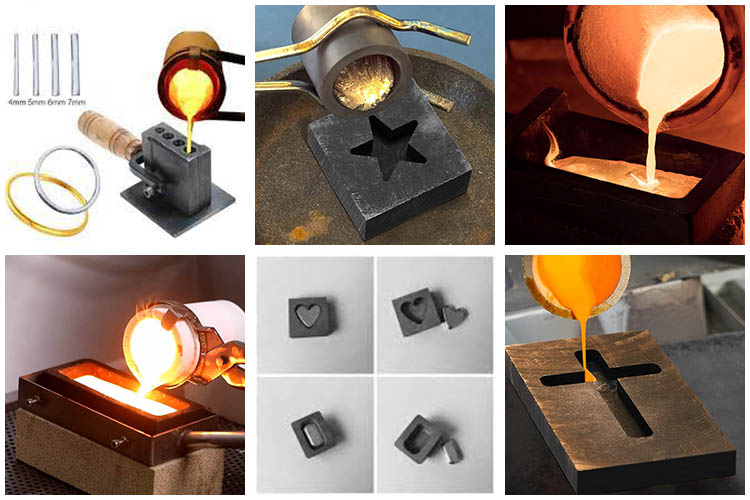

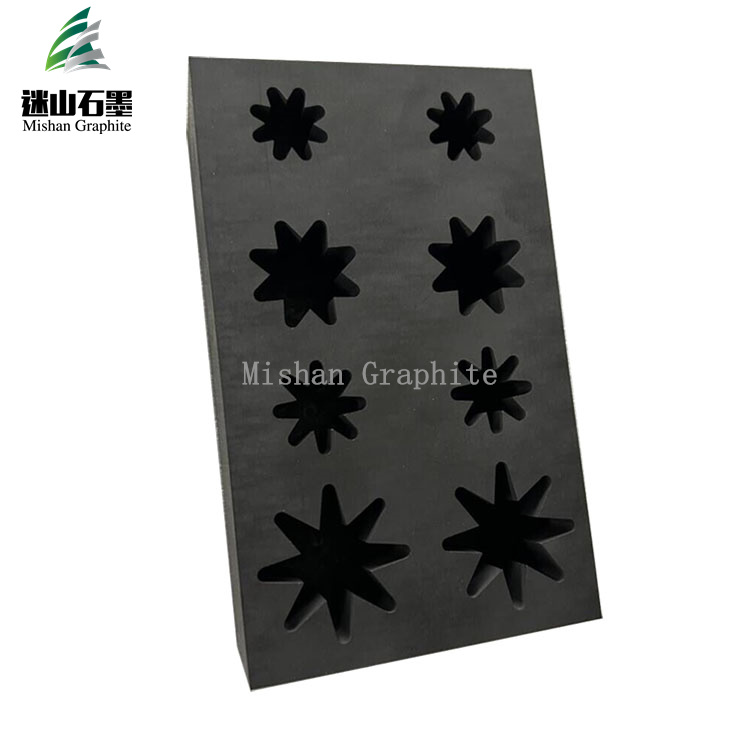

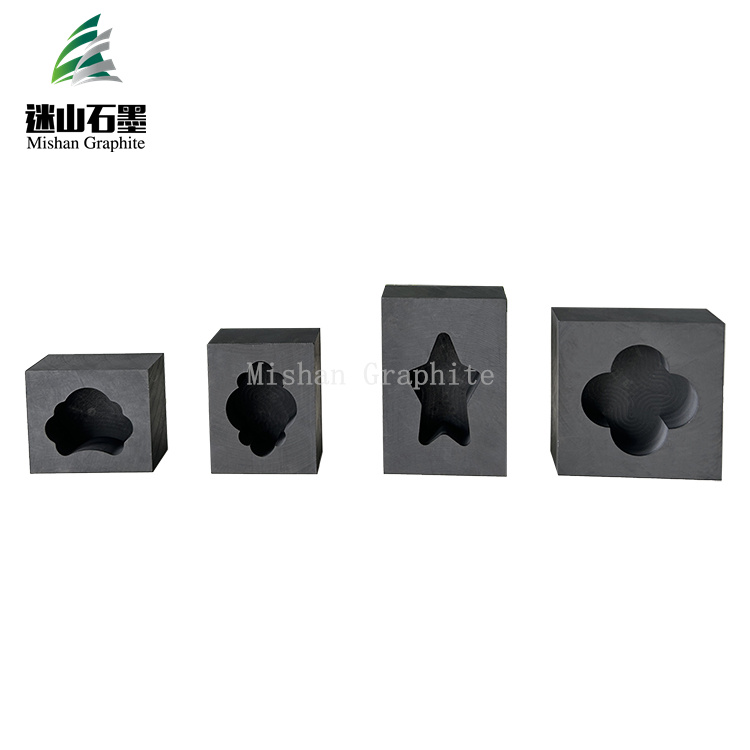

High density graphite mold for smelting

High density graphite mold for smelting is an essential component in the metallurgical industry. Graphite molds are widely used in smelting various types of metals including non-ferrous metals ...

Description

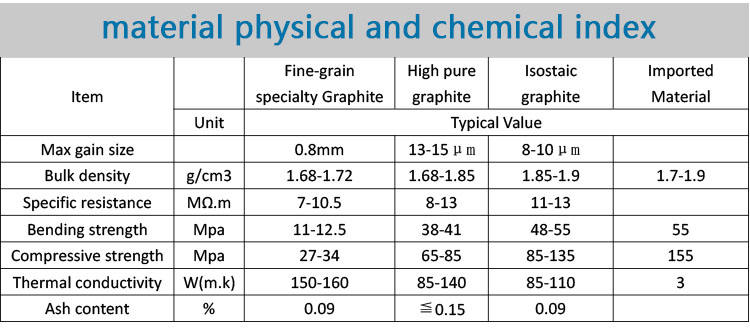

High density graphite mold for smelting is an essential component in the metallurgical industry. Graphite molds are widely used in smelting various types of metals including non-ferrous metals such as gold, silver, copper, zinc, and platinum. The high density graphite mold for smelting is an excellent material for the metallurgical industry because of its unique properties such as high temperature resistance, high thermal conductivity, and excellent electrical conductivity. The high temperature resistance of graphite is critical in smelting because it helps to ensure that the mold does not deform or crack under high temperature and pressure. The performance of the mold during the smelting process is essential to ensure the quality of the final product. The ability to withstand high temperatures ensures that the mold maintains its structural integrity throughout the smelting process, thus ensuring consistency in the final product. The high thermal conductivity of graphite is also an important feature that makes it an ideal material for smelting molds. The thermal conductivity of graphite helps to ensure that the heat is distributed evenly throughout the mold. This even distribution of heat ensures that the molten metal cools uniformly, reducing the likelihood of imperfections and inconsistencies in the final product. Another important feature of high density graphite mold for smelting is its excellent electrical conductivity. This feature is essential to ensure that the mold maintains its temperature during the smelting process. The electrical conductivity of graphite helps to provide an even flow of electricity throughout the mold, which ensures that the mold maintains a consistent temperature during the smelting process. Moreover, the use of graphite molds in smelting reduces the amount of waste generated during the process. Graphite molds can be reused multiple times, reducing the amount of waste generated during the smelting process and making the process much more environmentally friendly. In conclusion, the use of high density graphite mold for smelting has proven to be a game-changer in the metallurgical industry. The unique properties of graphite make it an ideal material for smelting molds, ensuring that the smelting process is consistent, efficient and environmentally friendly. The importance of high density graphite mold in the metallurgy industry cannot be overstated, and its use is set to continue growing in the coming years. PACKAGE: DELIVERY TIME:

Veneer cases or wooden cases or according to customers’ requirement.

3-20 days after confirming order,detail delivery date should be decided according to

production season and order quantity.