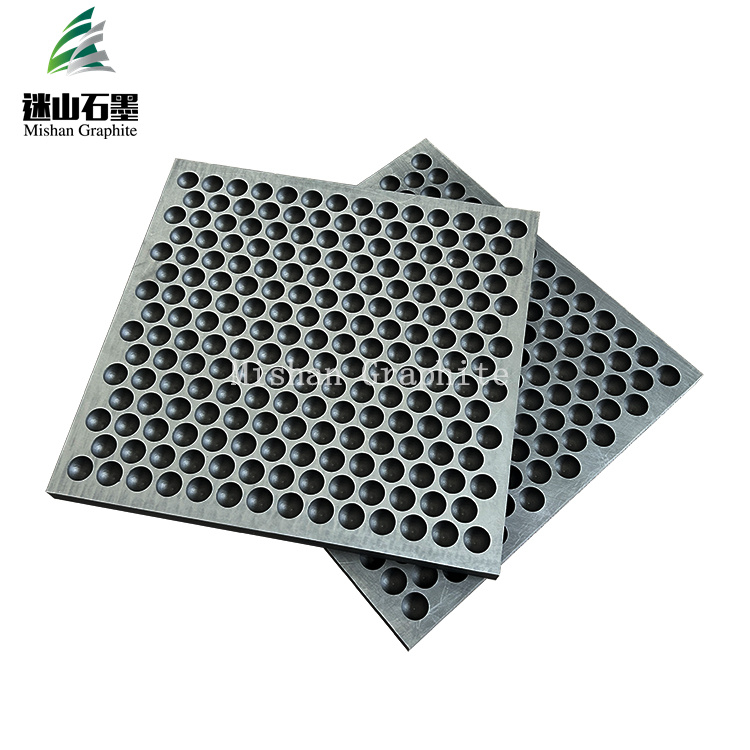

Wear resistance graphite mould for industry

Wear-resistant graphite molds are becoming more and more popular in the manufacturing industry. Graphite molds are ideal for manufacturing products that require high precision. The wear-resista...

Description

Wear-resistant graphite molds are becoming more and more popular in the manufacturing industry. Graphite molds are ideal for manufacturing products that require high precision. The wear-resistant properties of graphite molds make them ideal for industries that use abrasives in their manufacturing processes. PACKAGE: DELIVERY TIME:

The manufacturing industry is constantly evolving, and companies are always looking for ways to improve production processes and increase efficiency. Graphite molds have proven to be a valuable asset in the manufacturing process, especially in industries that require high precision and accuracy. These molds are used to produce a variety of products such as automotive parts, aerospace parts, and medical devices.

One of the significant advantages of graphite molds is their ability to withstand the abrasive nature of some of the materials used in manufacturing. The wear-resistant properties of graphite molds ensure they last longer and require less maintenance than other traditional mold materials. This durability means lower maintenance and replacement costs in the long run, making graphite molds a more cost-effective option for manufacturing companies.

Graphite molds are also known for their excellent heat resistance. They can withstand high temperatures without breaking down or losing their properties. This makes them ideal for use in industries requiring high temperature applications, such as the aerospace industry.

In addition to durability and heat resistance, graphite molds offer superior accuracy and precision compared to other mold materials. Graphite molds are capable of creating complex shapes and sizes, giving manufacturers the flexibility to create complex designs and products that require high-precision finished products.

In summary, graphite molds are becoming increasingly popular for use in manufacturing due to their durability, heat resistance, accuracy, and cost-effectiveness. Graphite molds are able to withstand abrasives and high temperatures, making them an excellent investment for companies looking to improve their manufacturing processes, increase efficiency and reduce production costs, while still maintaining high precision in the final product.

Veneer cases or wooden cases or according to customers’ requirement.

3-20 days after confirming order,detail delivery date should be decided according to

production season and order quantity.