Carbon Graphite Rotors & Vanes Manufacturing

What are carbon graphite rotors and vanes? Let’s learn about it through its manufacturing process! Carbon graphite rotors and vanes are made from a raw material produced by heating a mixture o...

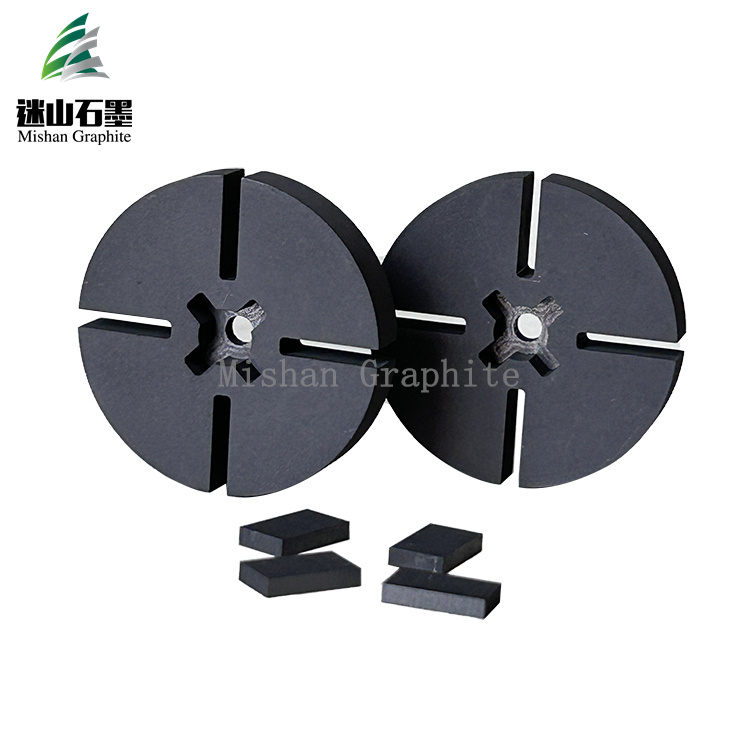

Description

What are carbon graphite rotors and vanes? Let’s learn about it through its manufacturing process!

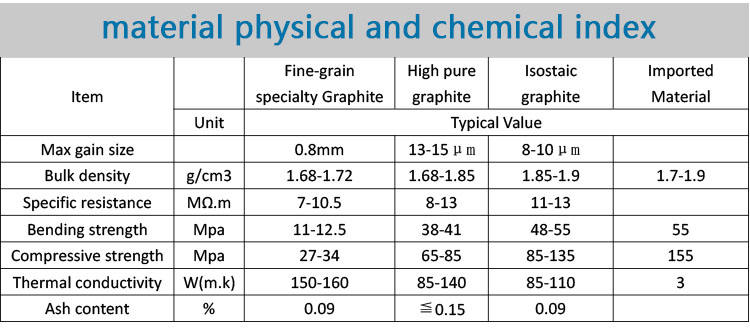

Carbon graphite rotors and vanes are made from a raw material produced by heating a mixture of graphite powder and binder at extremely high temperatures. This material is high quality, strong and lightweight, making it perfect for making carbon graphite rotors and vanes. . Of course, application requirements are different and the grades of graphite materials used are also different.

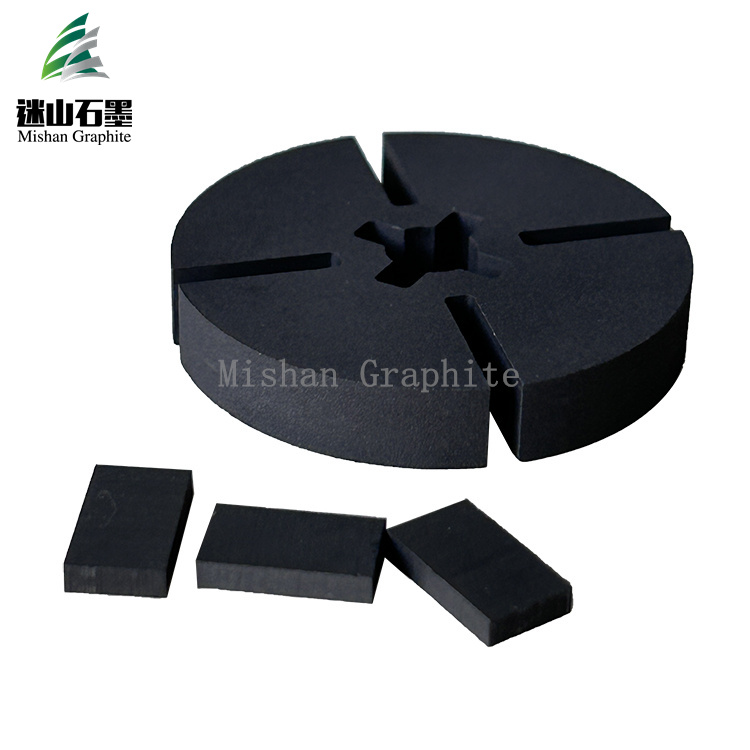

The next step is to process the graphite material into the desired shape. This typically involves using computer-controlled cutting equipment to ensure that the carbon graphite rotors and blades are precisely shaped and have a smooth surface. After processing, the graphite rotors and blades are carefully inspected to ensure they meet required specifications for dimensional accuracy and surface finish.

Finally, the carbon graphite rotor and vanes are impregnated with a resin binder to further enhance their strength and durability. The dipping process involves soaking the parts in a specially formulated resin solution and then drying them at high temperatures. This creates a strong adhesive that helps prevent damage and extend the life of the part.

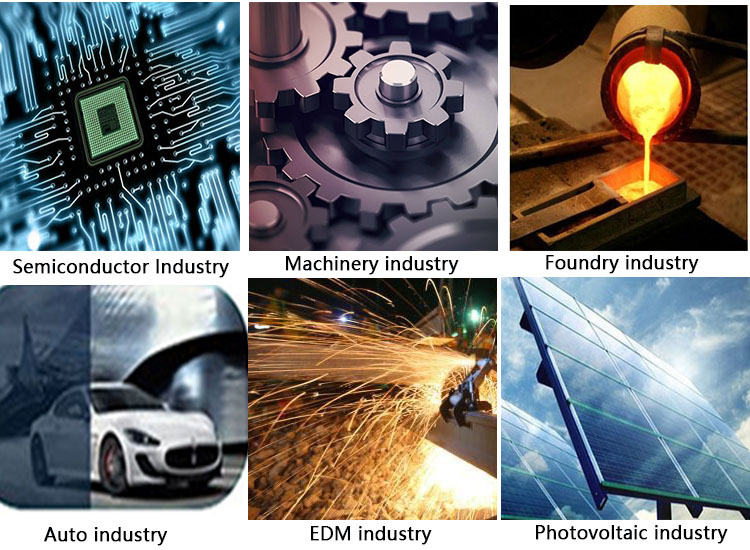

Through the above explanation, we can explain the question “why carbon graphite rotors and vanes are used as key components in a variety of industries such as aerospace, chemical processing, and power generation.”

Overall, carbon graphite rotors and vanes are highly regarded for their superior strength, durability, and corrosion resistance. Ideal for fluid handling equipment in a variety of industries, their high performance and reliability help minimize downtime and increase efficiency. By learning more about the manufacturing process of these parts, we can appreciate the engineering excellence that goes into making them and the value they bring to the industries that use them.