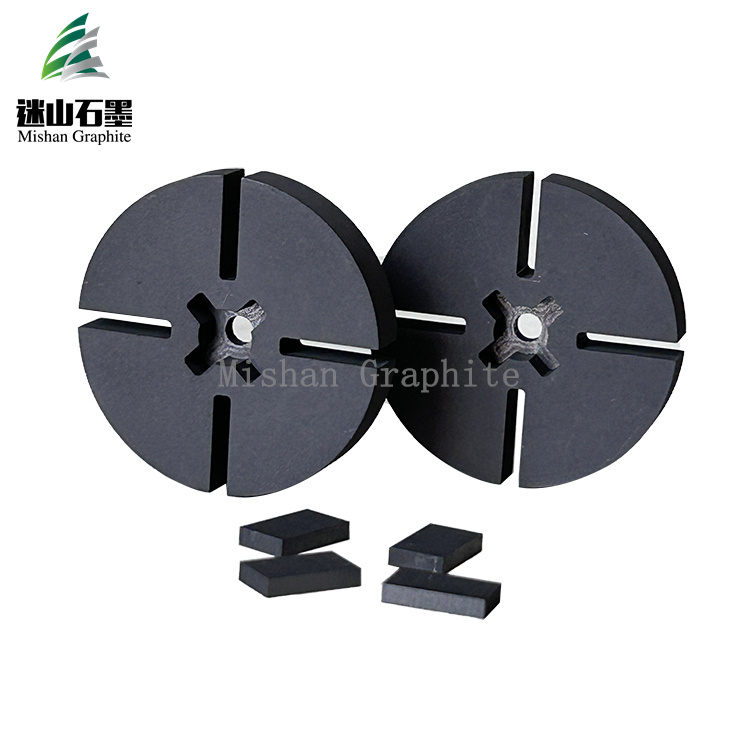

Graphite rotor for aluminium degassing

The graphite rotor is an important component in the aluminum degassing process. As the use of aluminum in the market grows, the need for high-quality and cost-effective aluminum degassing metho...

Description

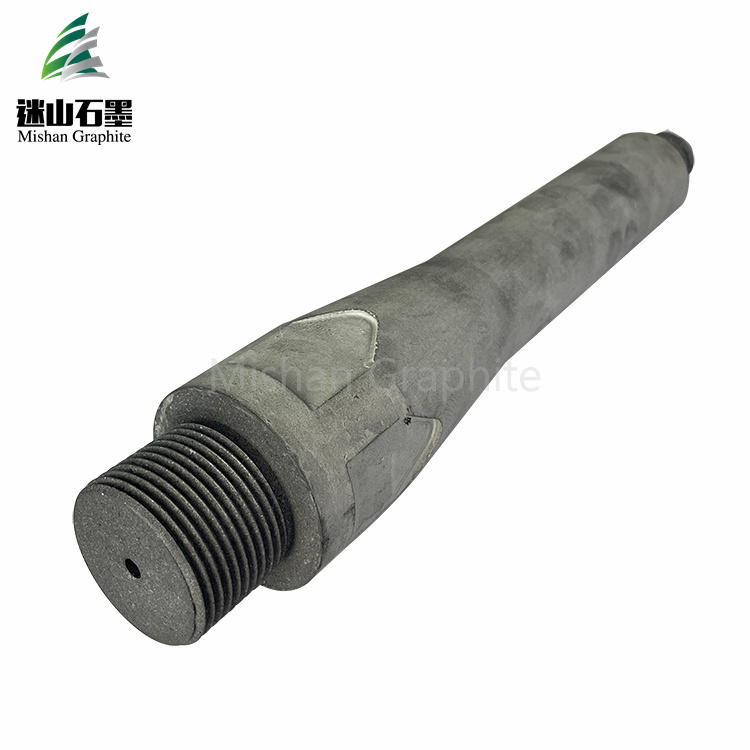

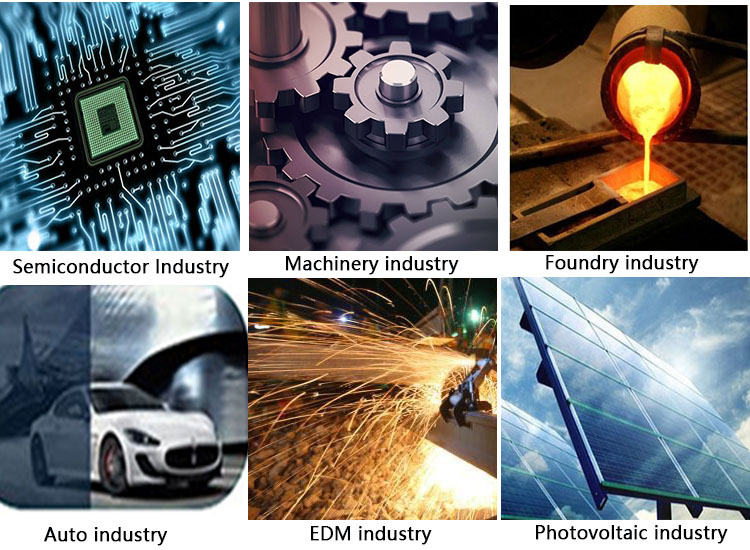

The graphite rotor is an important component in the aluminum degassing process. As the use of aluminum in the market grows, the need for high-quality and cost-effective aluminum degassing methods for aluminum casters becomes increasingly important. Therefore, the amount of graphite rotors used for aluminum degassing is also increasing. PACKAGE: DELIVERY TIME:

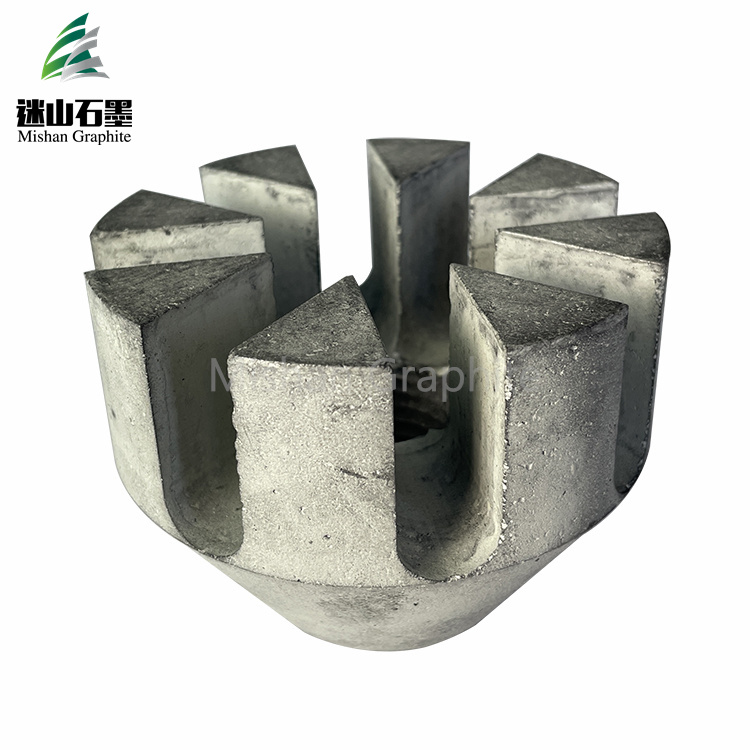

The graphite rotor for aluminum degassing is an important tool in the dehydrogenation process of aluminum liquid. Its main function is to stir the metal solution and make the hydrogen gas escape in the form of bubbles. Aluminum degassing is mainly used to remove hydrogen contained in liquid aluminum, because hydrogen will have a negative impact on the mechanical properties of aluminum.

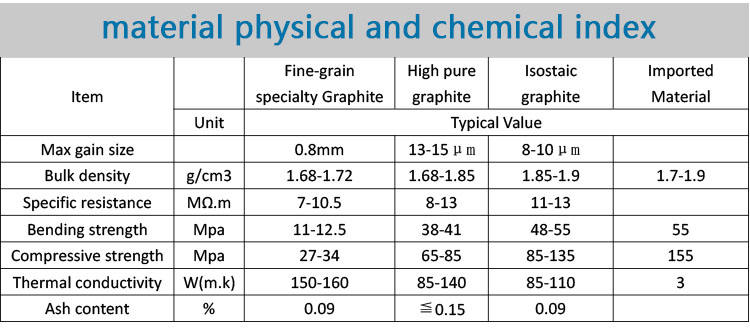

There are many benefits to using graphite rotors in aluminum degassing. First, graphite is an excellent thermal conductor, ensuring that the rotor can effectively transfer heat into the metal. This speeds up the degassing process and reduces energy consumption. Additionally, graphite is resistant to high temperatures and chemical attack, making it a reliable choice for use in harsh environments where molten aluminum exists.

Another advantage of the graphite rotor is that it can be easily machined and shaped to fit different aluminum degassing systems. This flexibility also makes it a cost-effective option for manufacturers, as a single rotor can be used across multiple systems.

Finally, using graphite rotors in aluminum degassing can improve product quality. By removing hydrogen from the molten metal, the mechanical properties of the final aluminum product are enhanced, resulting in a stronger, more durable material.

Veneer cases or wooden cases or according to customers’ requirement.

3-20 days after confirming order,detail delivery date should be decided according to

production season and order quantity.