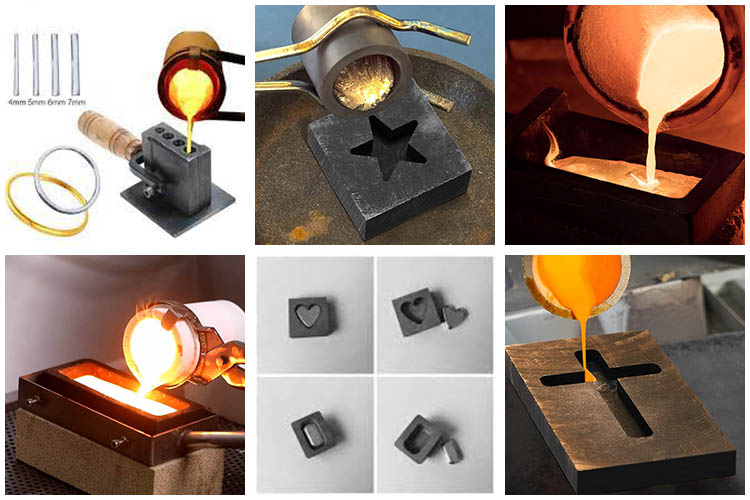

Graphite crucible for melting furnace

Graphite crucibles for melting furnaces are used in furnaces in various industries because of their good heat resistance, high thermal conductivity and stable chemical properties. Graphite cruc...

Description

Graphite crucibles for melting furnaces are used in furnaces in various industries because of their good heat resistance, high thermal conductivity and stable chemical properties. Graphite crucible for melting furnace is an important part of the melting process and plays an important role in the success of the melting process. PACKAGE: DELIVERY TIME:

Graphite crucible can withstand the high temperatures generated during the melting process of different materials such as metals, alloys, and glass. It is also used in the production of silicon carbide, silicon and other technical ceramics. Materials are selected based on the melting point of the substance and the level of chemical resistance required.

In terms of thermal conductivity, graphite crucibles are the best choice for rapid heating and cooling processes due to their high thermal conductivity. The graphite material ensures uniform melting, thereby significantly reducing the risk of hot and cold spots in the melted material, thus providing better quality control during the melting process. It is also easy to handle due to its light weight and compact structure.

Graphite crucibles are also highly chemically resistant, allowing them to effectively handle and transport highly corrosive materials during the melting process. This resistance extends to refractory materials such as alumina, magnesium oxide, and zirconia. The stability of the graphite crucible is also crucial during the melting process, as damage to the crucible can affect the purity of the melted product. Therefore, it is crucial to ensure that the crucible is in good condition before and after each use.

In summary, the use of graphite crucibles in smelting furnaces significantly increases the success rate of the smelting process, resulting in better quality control and final product. The material’s high thermal conductivity, heat resistance and chemical stability make it the first choice for handling and melting processes in various industries. Proper handling and maintenance of graphite crucibles is necessary to ensure their longevity and effectiveness in the melting process.

Veneer cases or wooden cases or according to customers’ requirement.

3-20 days after confirming order,detail delivery date should be decided according to

production season and order quantity.