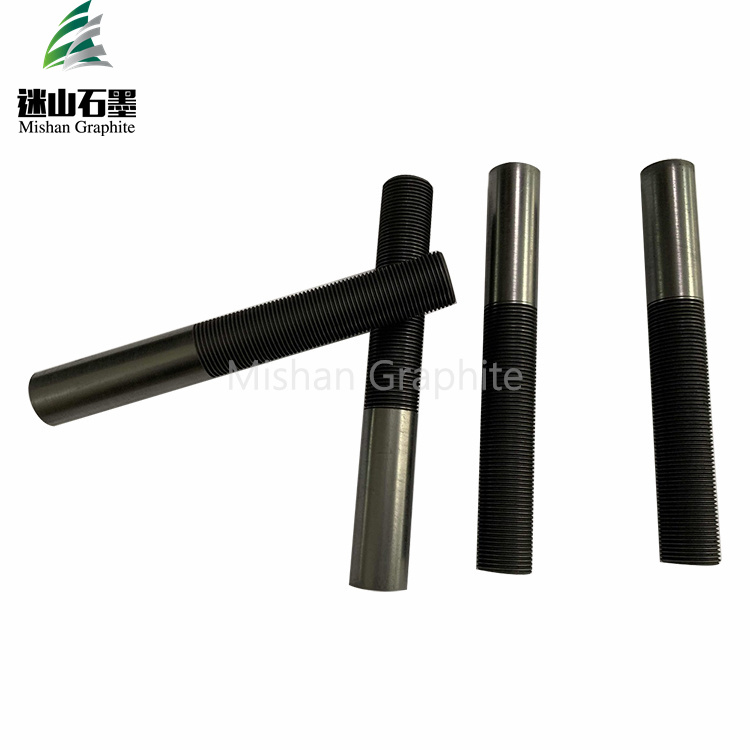

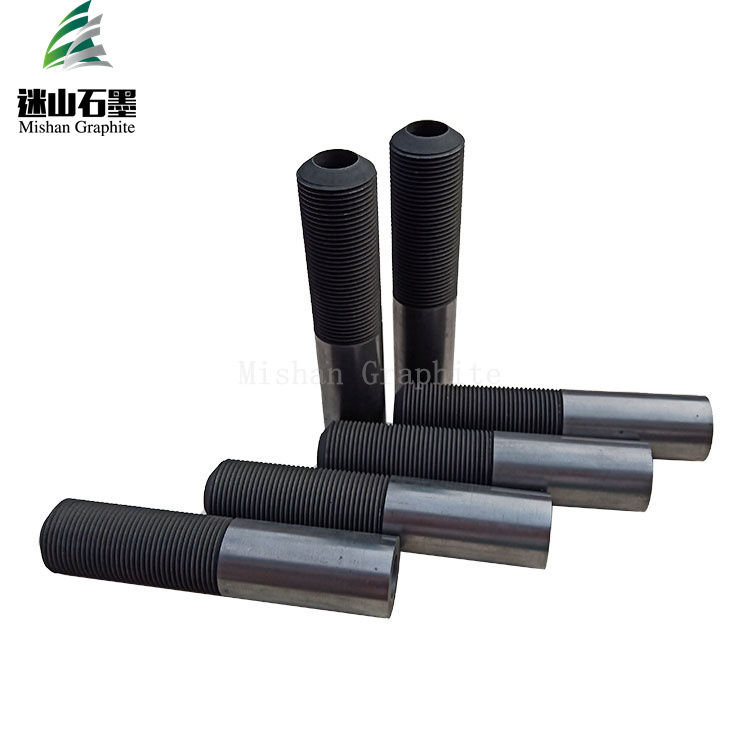

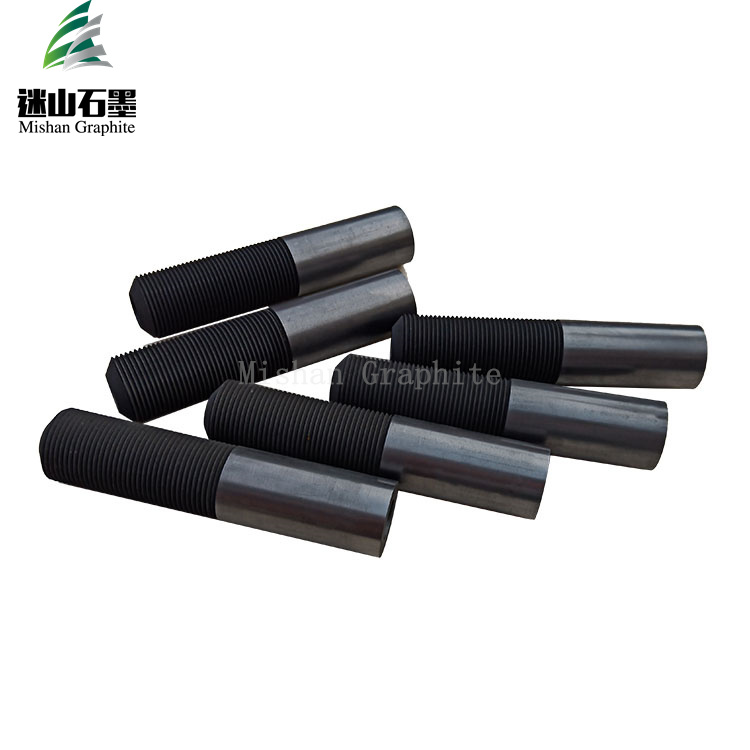

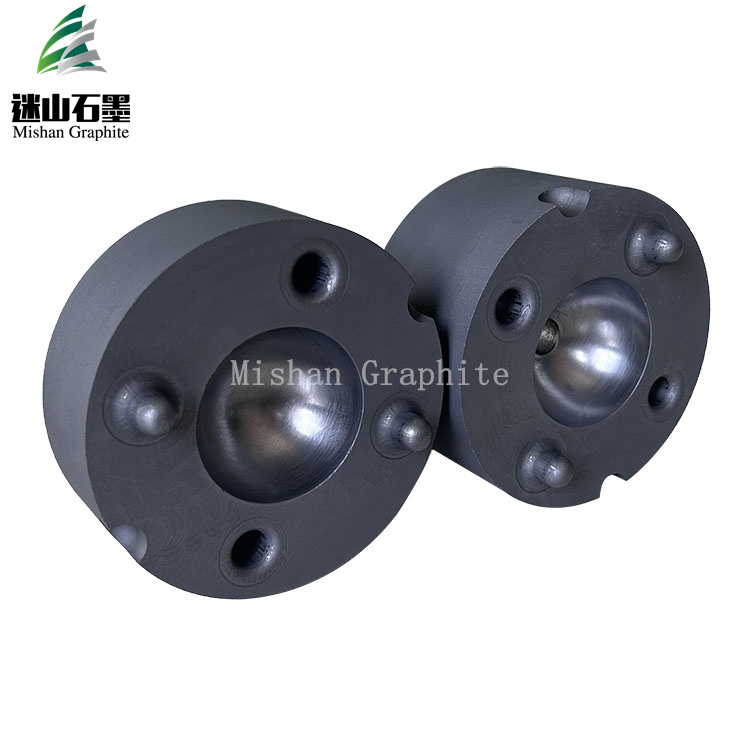

Graphite mould for continuous casting

What is the function of graphite mold for continuous casting? Graphite molds for continuous casting are mainly used in the continuous casting process to introduce molten steel into the mold to...

Description

What is the function of graphite mold for continuous casting? PACKAGE: DELIVERY TIME:

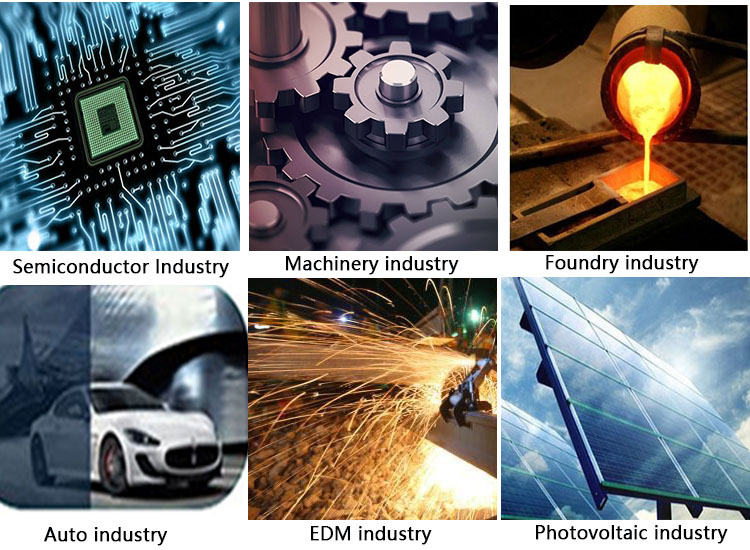

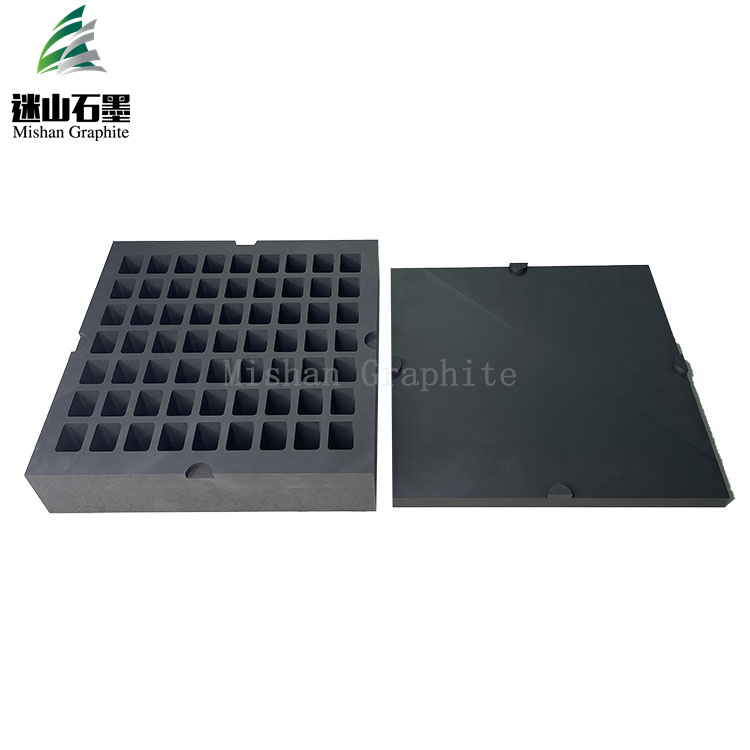

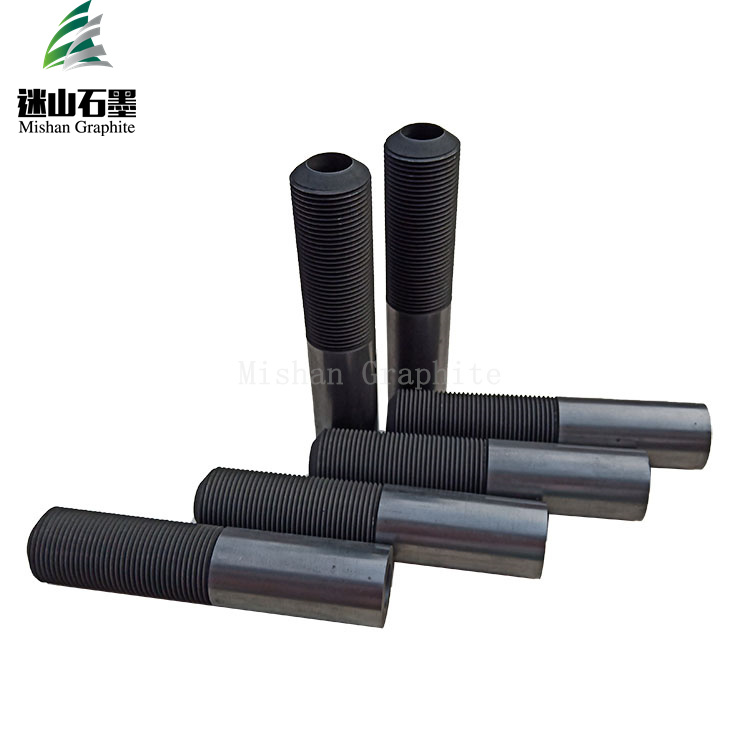

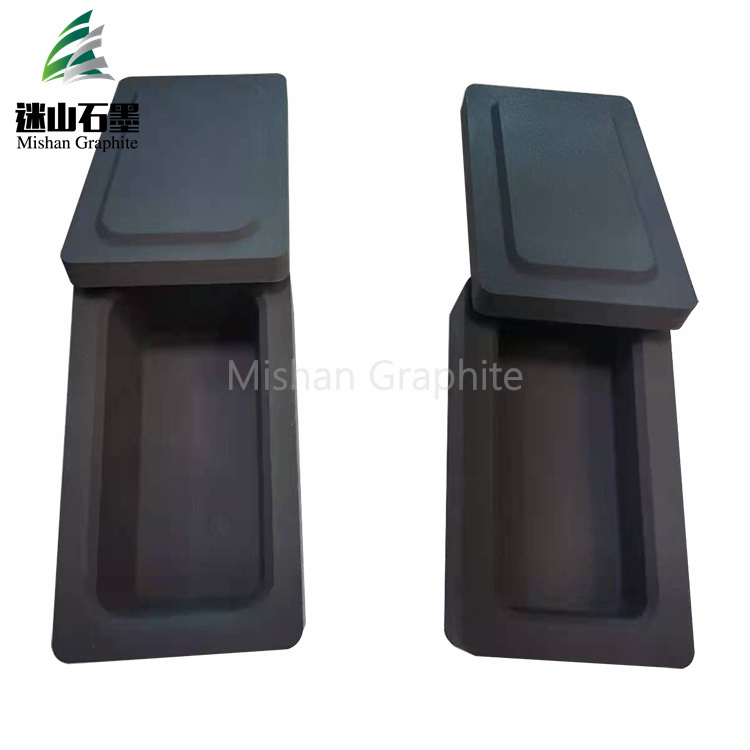

Graphite molds for continuous casting are mainly used in the continuous casting process to introduce molten steel into the mold to solidify it into semi-finished products, such as billets or slabs. The graphite mold is made of high-quality graphite material, which has excellent thermal conductivity and is resistant to chemical erosion and thermal shock. It plays a vital role in the production of high-quality steel.

Compared with other mold materials, what are the advantages of graphite molds?

1. Graphite mold has excellent heat transfer performance. This allows for faster solidification, thus improving product quality. These graphite molds also improve the surface finish, dimensional accuracy and repeatability of the casting process.

2. Graphite molds are highly customizable and can produce steel products of various sizes and shapes. They can be designed to withstand high casting pressures and temperatures, thereby increasing their durability and service life.

However, it is worth noting that the performance of graphite molds for continuous casting is affected by a variety of factors, including the chemical composition of the steel being cast, casting speed and cooling conditions. Proper maintenance and cleaning of molds is also critical to ensuring their continued performance and longevity.

To sum up, graphite molds for continuous casting are an essential part of the manufacturing process of high-quality steel. They offer superior heat transfer properties, customization options and durability compared to other mold materials. However, their performance is affected by a variety of factors and require proper maintenance to ensure optimal results.

Veneer cases or wooden cases or according to customers’ requirement.

3-20 days after confirming order,detail delivery date should be decided according to

production season and order quantity.