Graphite mold for furnace

Furnace Graphite Molds - Graphite components in various furnaces. The furnace is an important tool for the melting and smelting of various metals. It is usually used to heat and melt various me...

Description

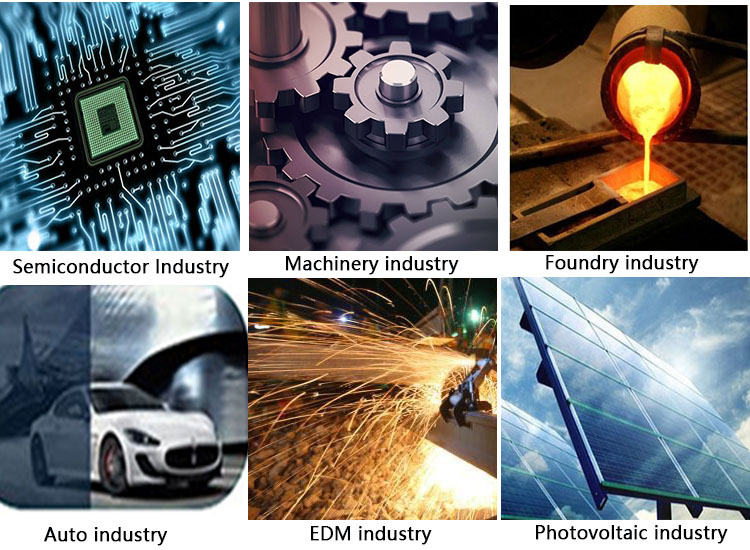

Furnace Graphite Molds – Graphite components in various furnaces. The furnace is an important tool for the melting and smelting of various metals. It is usually used to heat and melt various metals. In this process, various accessories in the furnace are required to proceed smoothly. Graphite components are key components of furnaces due to their high thermal conductivity, high resistance to thermal shock and excellent chemical resistance. So what are the graphite components in the furnace? PACKAGE: DELIVERY TIME:

1. Graphite crucible: Graphite crucible is a container used to hold and melt materials in a furnace. Crucibles made of graphite can withstand extremely high temperatures and thermal shock, making them ideal for melting metals and other materials. Graphite crucibles are also highly resistant to chemical corrosion and can be used to hold a variety of materials, including acids and alkalis.

2. Graphite heating element: Graphite heating element is an important component in the furnace that generates heat. Graphite heating elements are highly efficient and can withstand high temperatures while maintaining their shape and stability. They are widely used in vacuum furnaces, sintering furnaces and other high temperature applications.

3. Graphite Mold: Graphite mold is used to create specific shapes and sizes during the casting process. Graphite molds are commonly used for casting metals and ceramics due to their excellent thermal conductivity and resistance to thermal shock. Graphite molds can also be processed into complex shapes and patterns.

4. Graphite furnace frame: Graphite furnace frame is used to hold and transport materials in the furnace. Graphite racks are extremely durable and can withstand the high temperatures and harsh conditions found in furnaces. They are also chemically resistant and can be used to hold a variety of materials.

In summary, graphite components are critical to ensuring optimal furnace performance. Graphite crucibles, graphite heating elements, graphite molds, and graphite racks are just a few of the many components that can benefit from the use of graphite materials. Graphite’s high temperature resistance and chemical stability make it an ideal material for high temperature applications.

Veneer cases or wooden cases or according to customers’ requirement.

3-20 days after confirming order,detail delivery date should be decided according to

production season and order quantity.