Wear resistance graphite mold

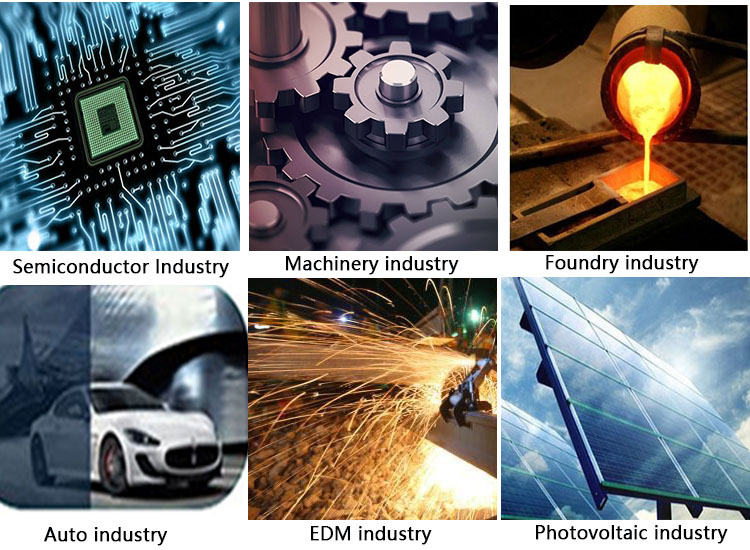

Wear-resistant graphite molds have the advantages of high hardness, high wear resistance, high thermal conductivity and low thermal expansion coefficient, so they are widely used in many fields...

Description

Wear-resistant graphite molds have the advantages of high hardness, high wear resistance, high thermal conductivity and low thermal expansion coefficient, so they are widely used in many fields: Mechanical processing field: Graphite molds are widely used in the field of mechanical processing and are mainly used to process hard materials, such as steel, iron, copper, aluminum, ceramics, etc. Graphite molds can be used for grinding, cutting, polishing, grinding and other processes, and can produce parts with high precision and high surface quality. PACKAGE: DELIVERY TIME:

Aerospace field: Graphite molds are also widely used in the aerospace field and can be used to manufacture graphite castings of various shapes and sizes, such as graphite tubes, graphite rods, graphite rings, etc.

Other fields: In addition to the above fields, graphite molds can also be used to manufacture gaskets (sealing gaskets) of various shapes, such as asbestos rubber gaskets, etc.; can be used to manufacture various wear-resistant parts, such as gears, bearings, bushings, etc. Friction surface; can be used to make the lining plate of the refractory brick furnace and the inner wall coating layer of the heat-resistant ladle; can be used to make materials for grinding wheels (grinding media); can be used as chemical raw materials directly in the petroleum industry as catalyst carriers and Reactor packing in some chemical industries, etc.

In short, wear-resistant graphite molds are widely used in many fields, and their excellent performance and characteristics make them an ideal choice in many fields.

Veneer cases or wooden cases or according to customers’ requirement.

3-20 days after confirming order,detail delivery date should be decided according to

production season and order quantity.