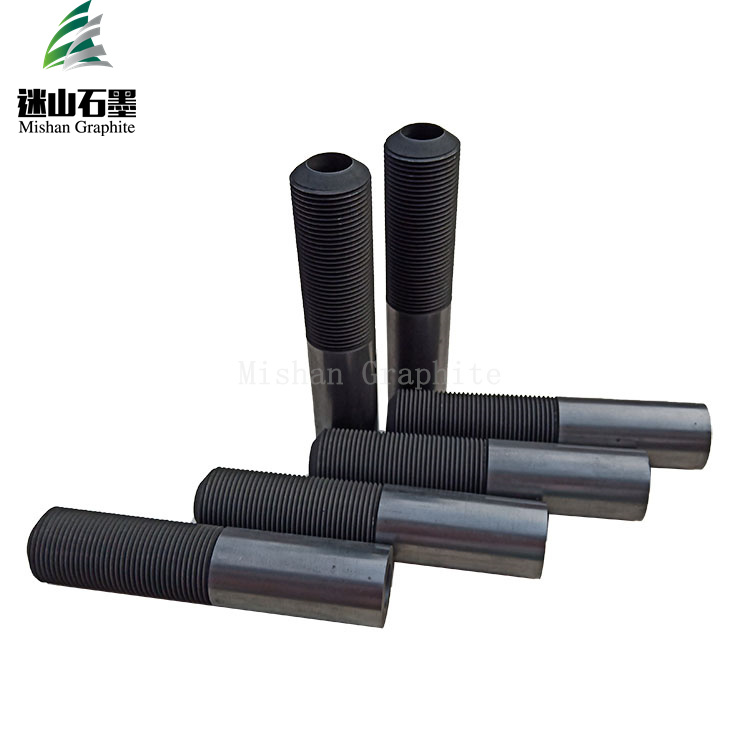

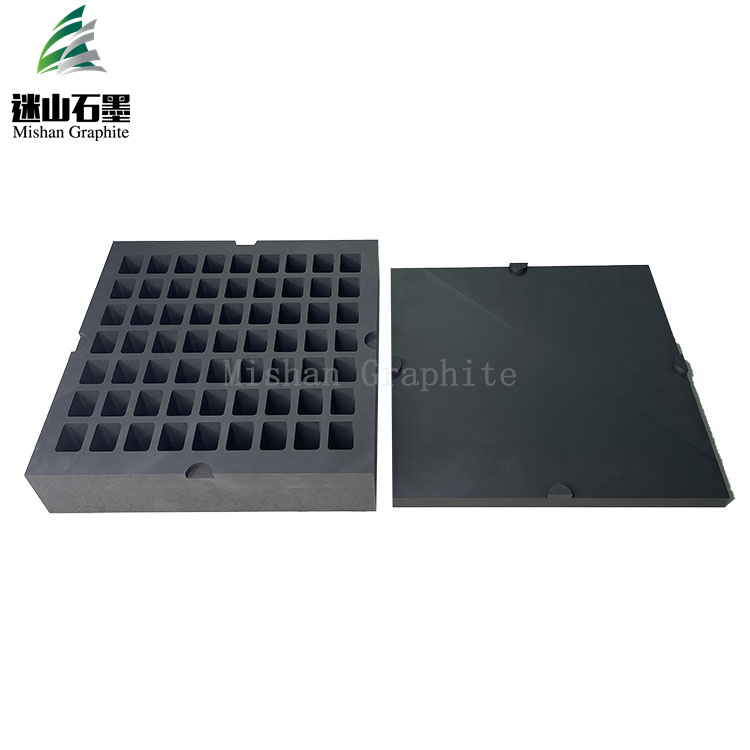

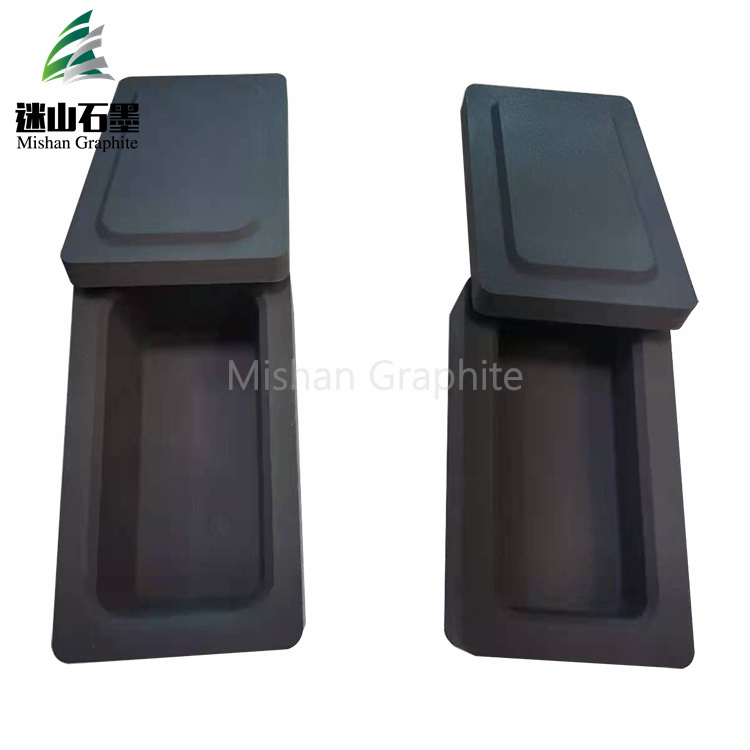

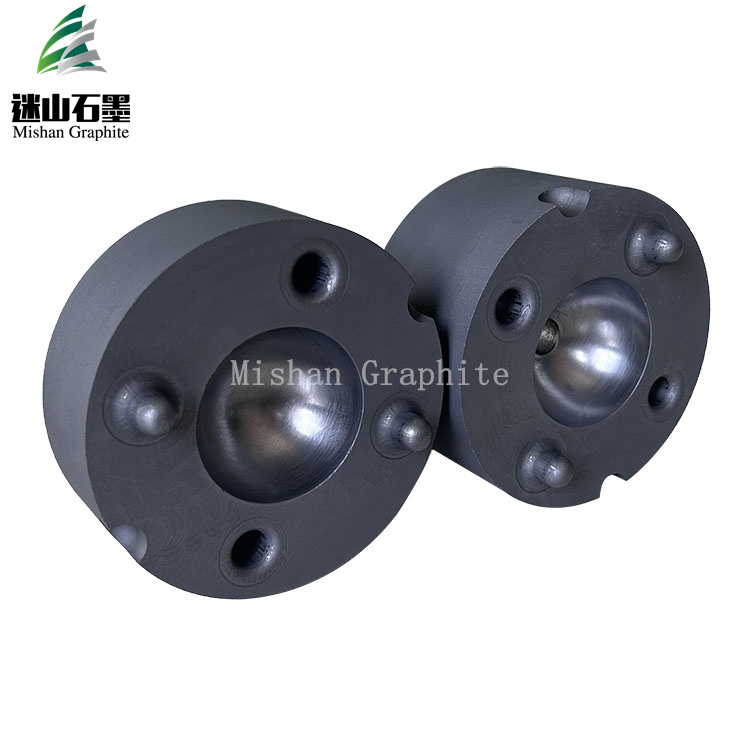

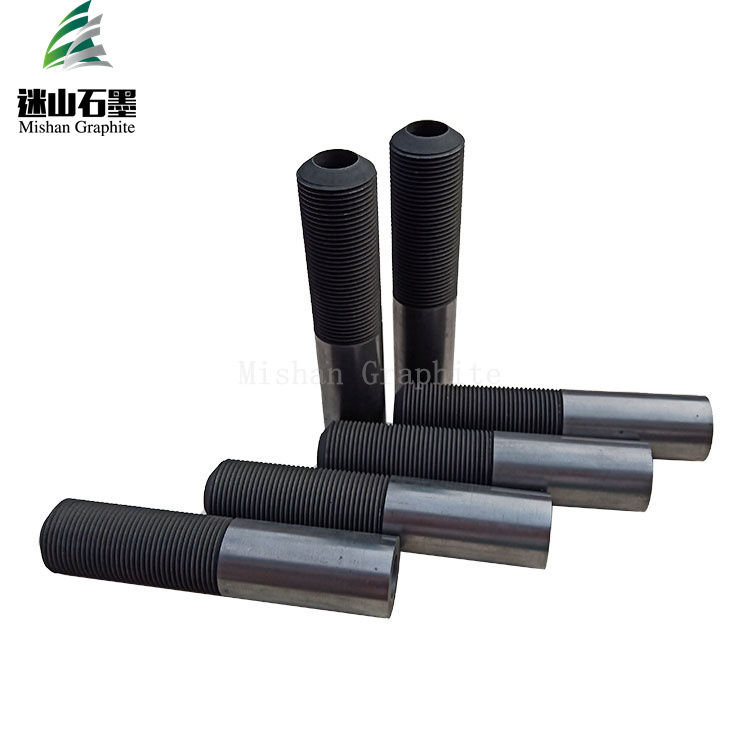

Graphite mold for centrifugal casting

Graphite molds for centrifugal casting are used to produce high quality metal castings. Centrifugal casting is a popular casting process nowadays. It uses centrifugal force to evenly distribute...

Description

Graphite molds for centrifugal casting are used to produce high quality metal castings. Centrifugal casting is a popular casting process nowadays. It uses centrifugal force to evenly distribute the metal solution into the mold, aiming to obtain parts with excellent density, structure and strength. PACKAGE: DELIVERY TIME:

Graphite molds for centrifugal casting are often used in centrifugal casting due to their excellent performance. Graphite is a very high temperature resistant material with excellent thermal conductivity and low thermal expansion coefficient. In addition, it has high wear resistance and corrosion resistance. These properties make it an ideal material for molds used in challenging environments where high temperatures, corrosive substances and abrasives exist.

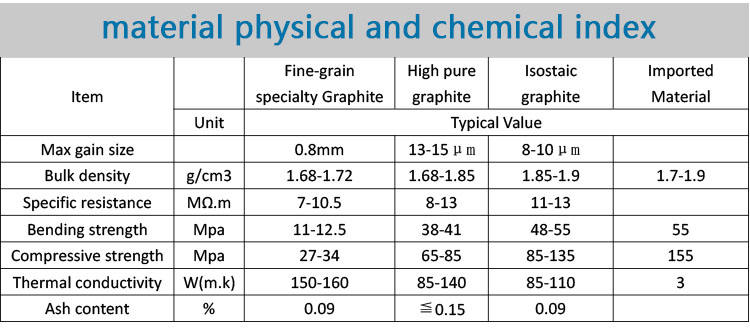

So how do we get high-quality graphite molds for centrifugal casting? The first step is of course the selection of raw materials. We select high quality graphite blocks and process them into the correct size and shape of the required part.

The second step is the design of the graphite mold. The shape, size and complexity of the graphite mold must be confirmed clearly before production, because any deviation in the shape of the graphite mold will affect the quality of the final casting. Of course, the most important point is that the mold must be designed to withstand the high centrifugal force generated during the casting process.

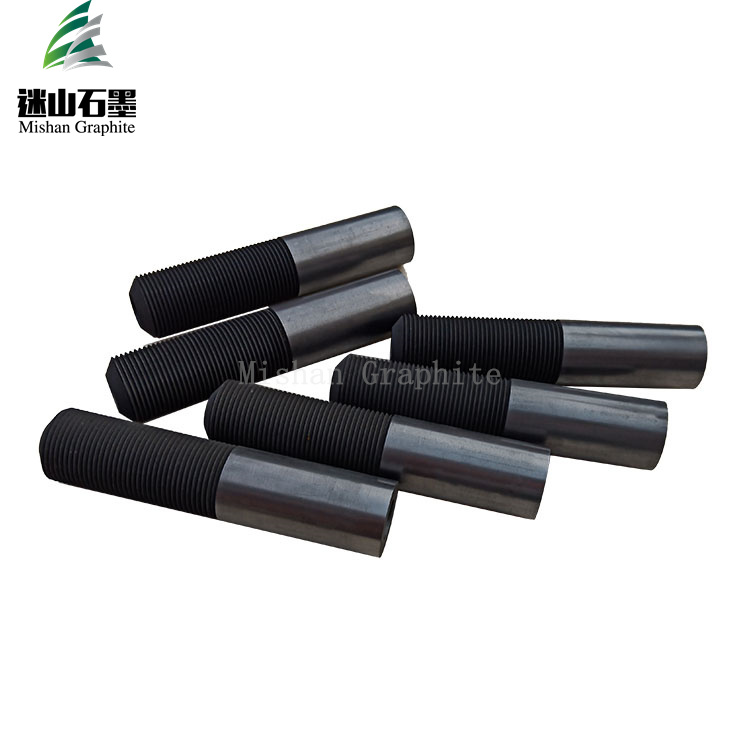

Graphite molds have a long life and only require proper care and maintenance. This is in stark contrast to other materials used for centrifugal casting molds, such as steel and ceramics, which have a much shorter service life and are more prone to failure.

From the above description, we understand that graphite molds for centrifugal casting are an important part of the production of high-quality metal parts. Graphite’s unique properties make it an ideal material for use in challenging casting environments.

Veneer cases or wooden cases or according to customers’ requirement.

3-20 days after confirming order,detail delivery date should be decided according to

production season and order quantity.