High purity graphite electrode plate

High purity graphite electrode plate are now well known to the public, so what are high purity graphite electrode plate? I think you don’t know much about it yet, so I will answer this question...

Description

High purity graphite electrode plate are now well known to the public, so what are high purity graphite electrode plate? I think you don’t know much about it yet, so I will answer this question for you next. PACKAGE: DELIVERY TIME:

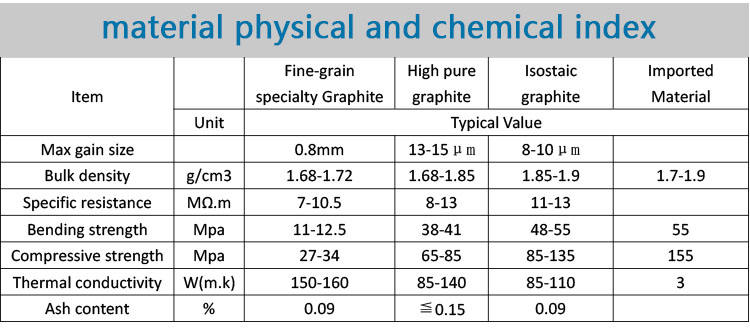

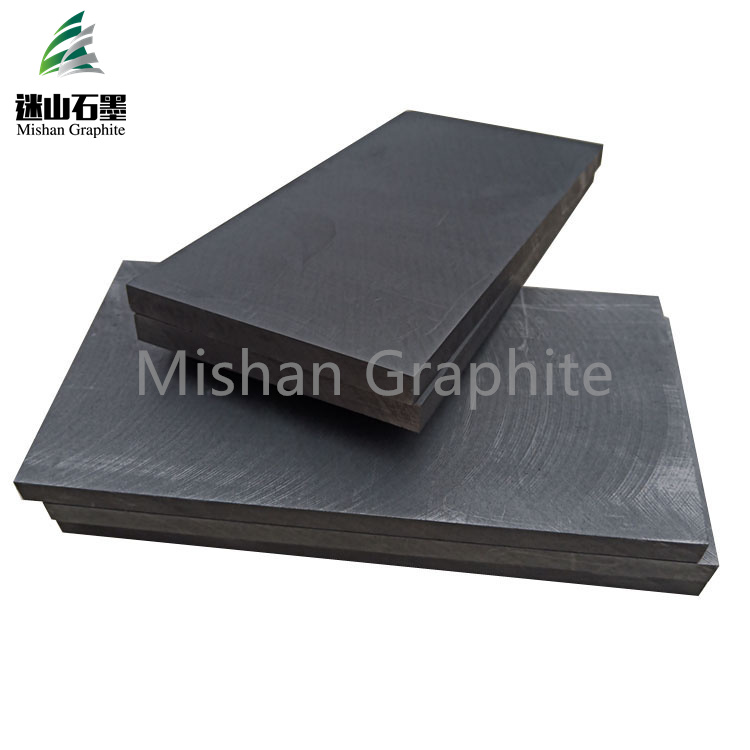

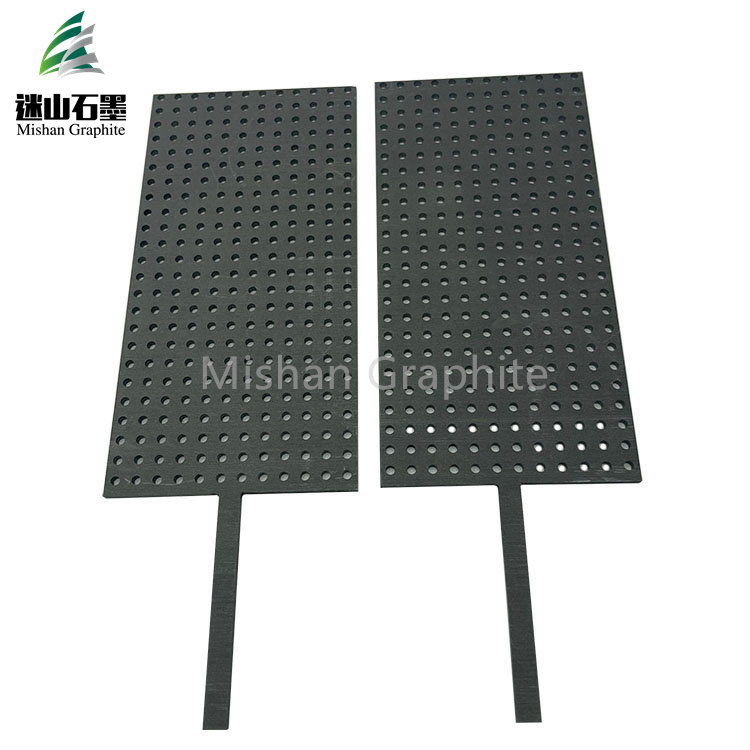

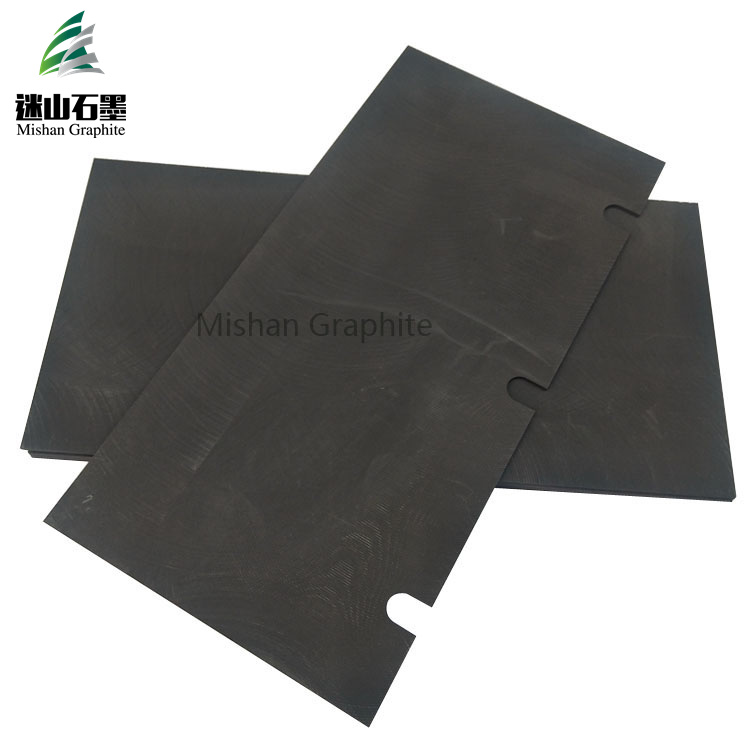

What exactly is a high purity graphite electrode plate? Simply put, it is a high-density, high-strength graphite plate formed into a flat rectangular shape. These graphite electrode plates are used to conduct electrical current through the furnace, and when electricity passes through the graphite plates, it heats and melts the steel. It is a graphite material widely used in electric arc furnace production. It is a critical component in the steel melting and refining process and helps ensure efficient operation of furnaces.

The advantages of high-purity graphite electrodes are as follows:

1. High purity graphite electrode plate can withstand extremely high temperatures. This is due to their unique physical and chemical properties that make them highly resistant to heat and corrosion. They are also very durable, which means they can be reused over long periods of time without suffering any major damage.

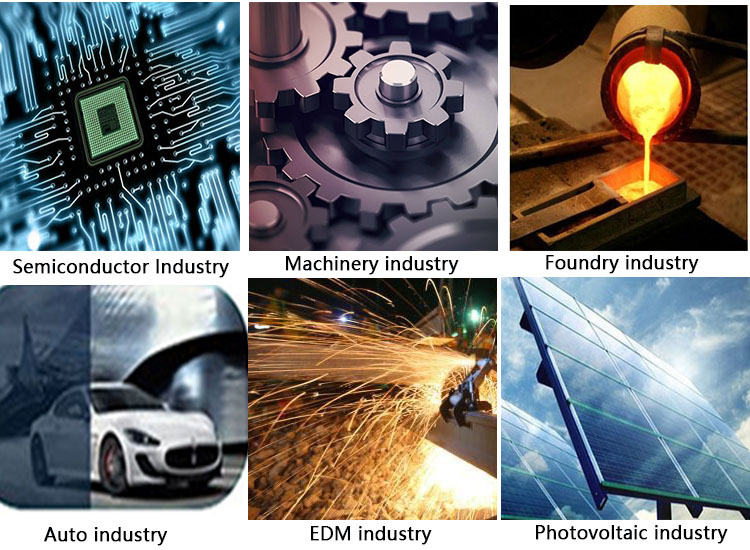

2. Graphite electrode plate versatility. They can be easily machined and shaped into a variety of different forms and sizes according to the user’s specific needs. This makes them ideal for use in a variety of different industries, including steelmaking, aluminum production, and even the production of certain chemicals and fuels.

Overall, the use of high purity graphite electrode plate is critical to efficient operation of electric arc furnaces. Whether you work in the steel industry or other industrial applications, it’s clear that these versatile and durable graphite materials are an important part of modern manufacturing and production processes.

Veneer cases or wooden cases or according to customers’ requirement.

3-20 days after confirming order,detail delivery date should be decided according to

production season and order quantity.