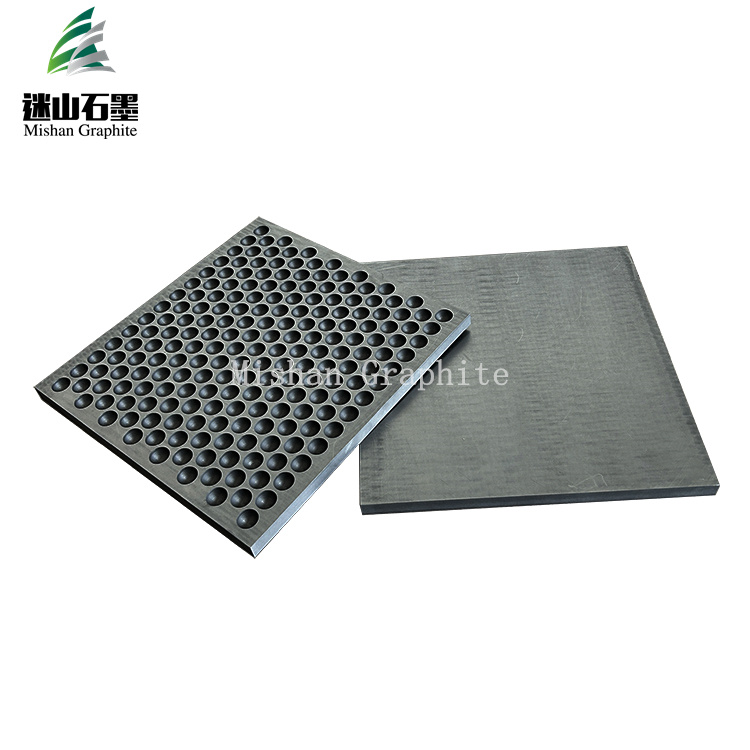

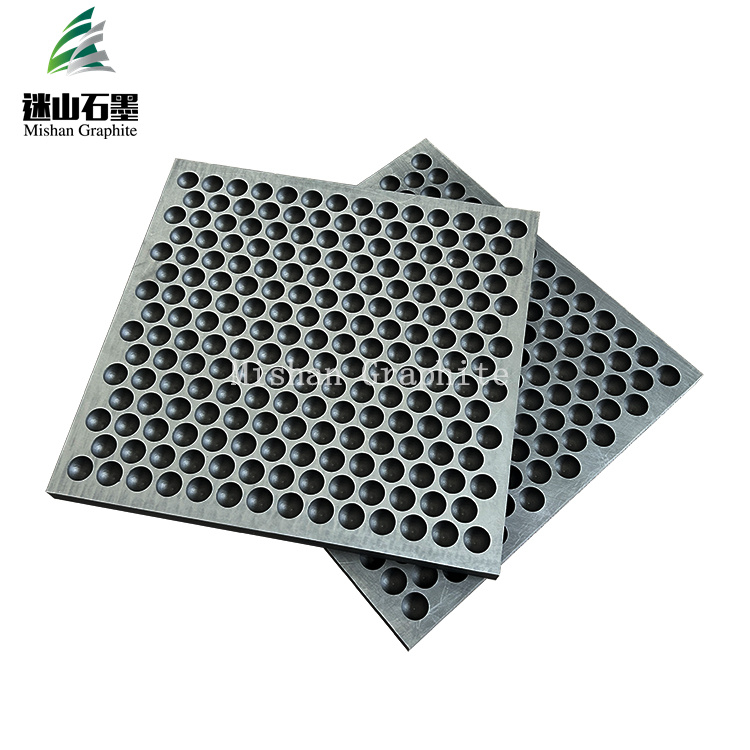

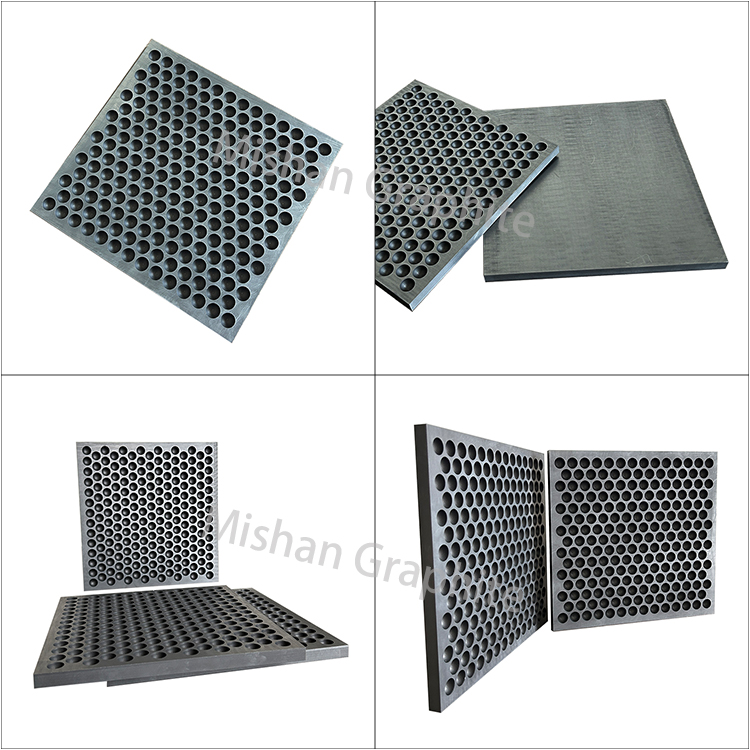

High purity graphite mold

High pure graphite mold is a kind of graphite mold with extremely high purity and extremely low impurity content. This type of graphite mold is widely used in the manufacturing industry due to ...

Description

High pure graphite mold is a kind of graphite mold with extremely high purity and extremely low impurity content. This type of graphite mold is widely used in the manufacturing industry due to its unique properties. PACKAGE: DELIVERY TIME:

One of the main advantages of high pure graphite mold is its excellent thermal conductivity, which allows the mold to be heated and cooled evenly and quickly. This feature is especially important for high-precision applications, where precise temperature control is critical for consistent results.

Another key advantage of high pure graphite mold is their excellent corrosion resistance and chemical reactivity. This makes it ideal for use in harsh environments where other materials may corrode or deteriorate over time. This type of mold can also withstand high temperatures without losing its structural integrity, making it ideal for high-temperature applications such as glass manufacturing and semiconductor processing.

In addition to excellent physical properties, high pure graphite mold have excellent machining properties and can easily produce complex shapes. This feature is particularly useful for applications requiring precise tolerances.

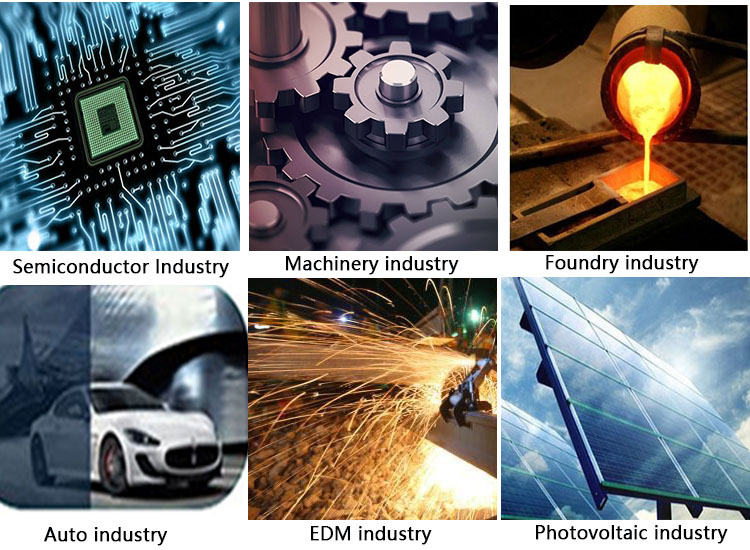

High pure graphite mold is widely used in aerospace, automotive, electronics and biomedical industries. It is used to manufacture a variety of products such as optical components, medical implants, advanced ceramics and complex machine parts.

In summary, high pure graphite mold offer a range of advantages that make them an ideal material for high-precision and high-temperature applications. Its unique properties, including excellent thermal conductivity, resistance to corrosion and chemical reactivity, and excellent machinability, make it the first choice in multiple industries. As high pure graphite mold become increasingly popular, it will certainly remain an important part of modern manufacturing processes.

Veneer cases or wooden cases or according to customers’ requirement.

3-20 days after confirming order,detail delivery date should be decided according to

production season and order quantity.