Vibration moulding graphite block

Graphite block, the first thing we think of when mentioning this is its versatility and wide range of applications. It is famous both at home and abroad for its high thermal conductivity, low r...

Description

Graphite block, the first thing we think of when mentioning this is its versatility and wide range of applications. It is famous both at home and abroad for its high thermal conductivity, low resistance and excellent machinability. PACKAGE: DELIVERY TIME:

There are many types of graphite blocks. Today we are going to focus on vibration molded graphite blocks. The graphite block is made by mixing graphite powder with a binder and placing it into a mold, then vibrating the mold on a high-frequency machine to evenly distribute the graphite particles within the mold and remove any air pockets. The final product is a solid block of graphite material with uniform density and excellent strength.

So, what makes vibration-formed graphite blocks such a high-performance material? We explain this by understanding its features and advantages.

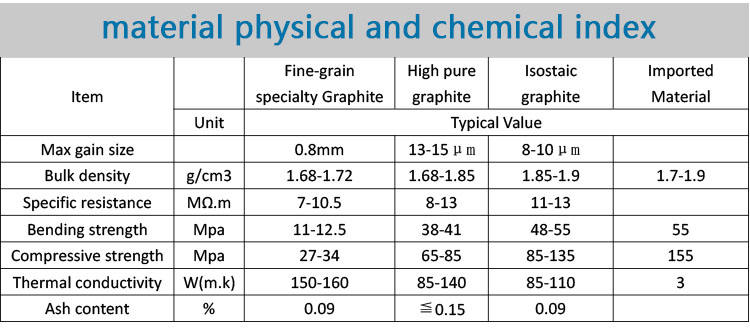

1. High density and strength – As mentioned earlier, the vibration molding process ensures that the graphite particles are evenly distributed within the mold, thereby forming a block with uniform density and excellent strength. This makes it ideal for applications requiring high loads and pressures.

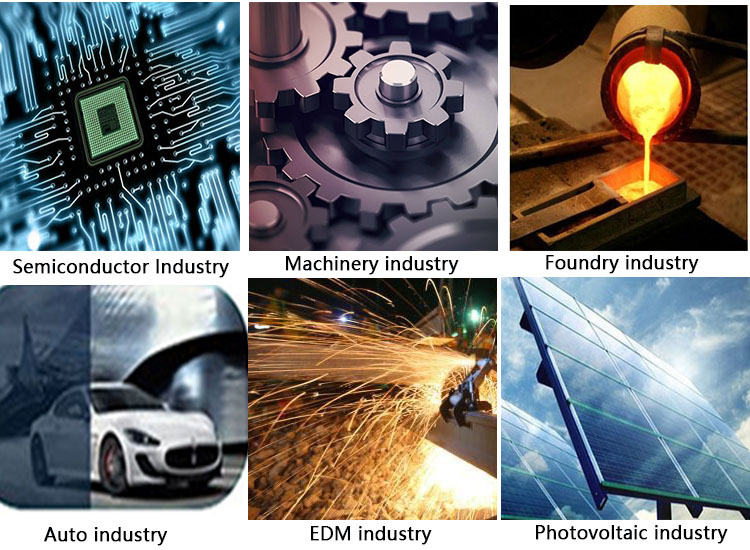

2. High thermal conductivity – Graphite is an excellent thermal conductor, and vibration-formed graphite blocks are no exception. Its high thermal conductivity makes it ideal for use in a variety of high temperature applications such as foundry work, metallurgical processes, etc.

3. Low Resistance – Graphite is also an excellent conductor of electricity and has very low resistance. This makes vibration-formed graphite blocks an ideal material for applications requiring high electrical conductivity, such as in the electronics industry.

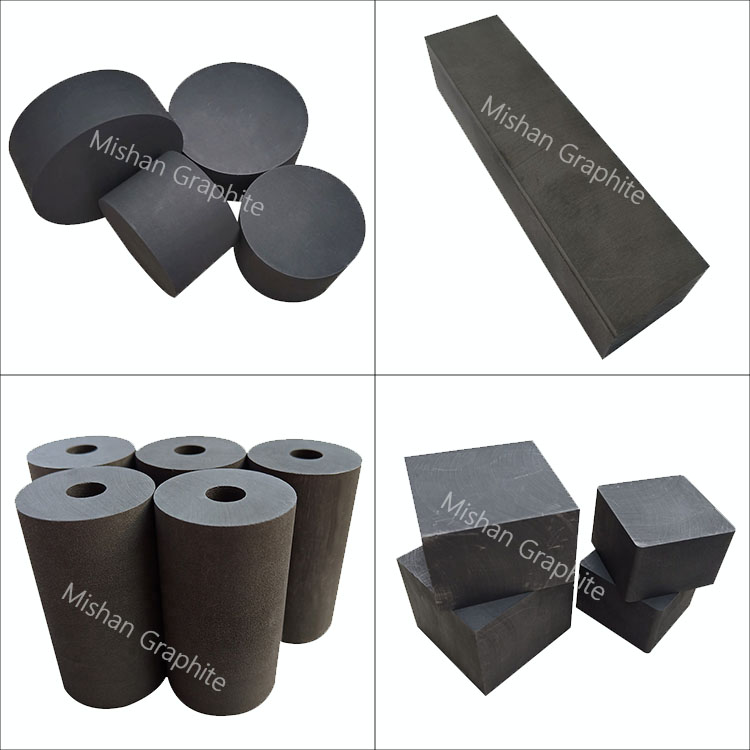

4. Processability – Graphite is a naturally soft and easy to process material, and the vibration molding process only enhances this property. It can be easily machined into a variety of shapes and sizes using standard machining tools, making it extremely versatile and cost-effective.

5. Corrosion Resistance – Graphite is also highly resistant to corrosion and chemical attack, making it the material of choice for a variety of chemical processing applications.

Veneer cases or wooden cases or according to customers’ requirement.

3-20 days after confirming order,detail delivery date should be decided according to

production season and order quantity.