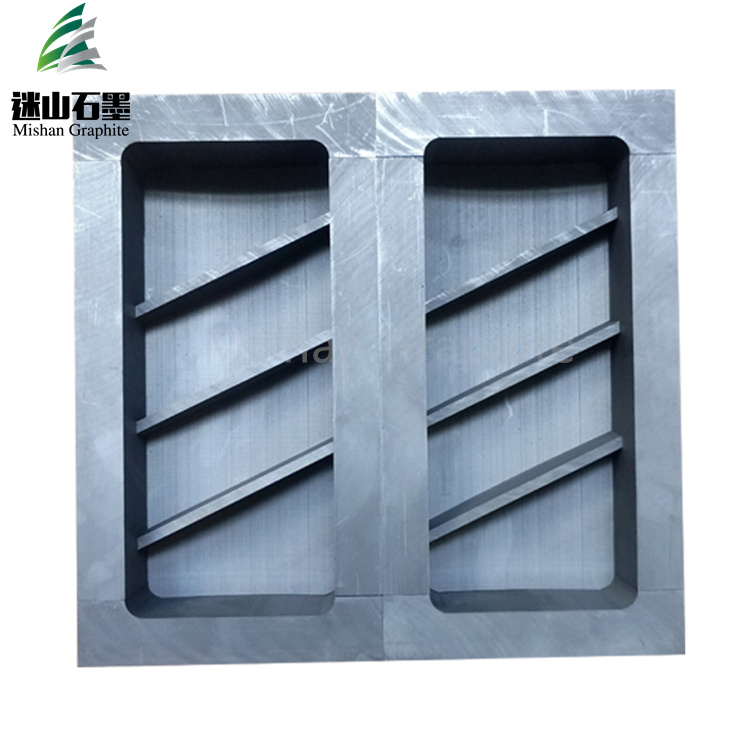

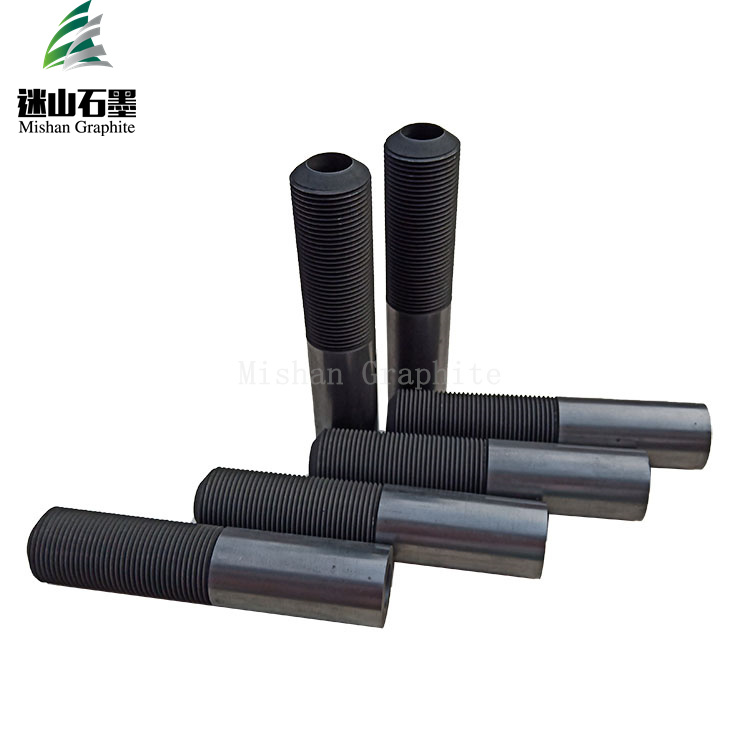

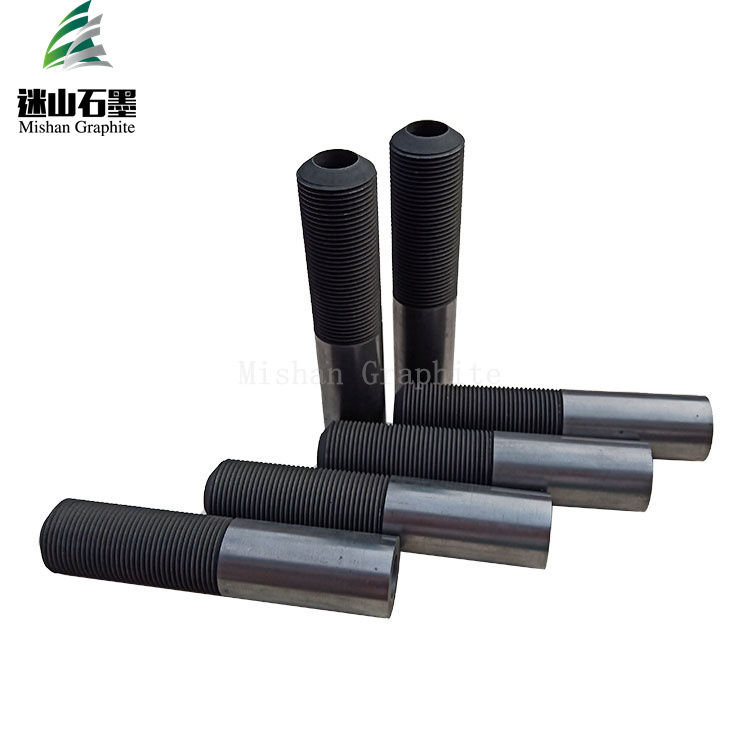

Diamond saw bit segment graphite mould

Diamond saw blades are an essential tool for cutting and shaping hard materials such as concrete, granite, and metal. Diamond saw blades are becoming increasingly popular due to their superior ...

Description

Diamond saw blades are an essential tool for cutting and shaping hard materials such as concrete, granite, and metal. Diamond saw blades are becoming increasingly popular due to their superior speed and precision capabilities compared to traditional saw blades. The diamond saw blade tip is an integral part of the saw blade and plays a vital role in determining the efficiency and performance of the saw blade. PACKAGE: DELIVERY TIME:

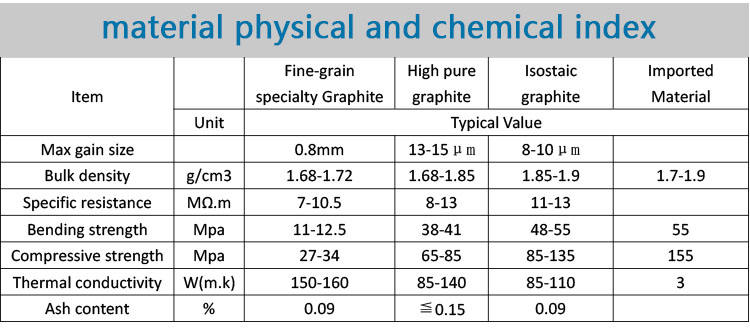

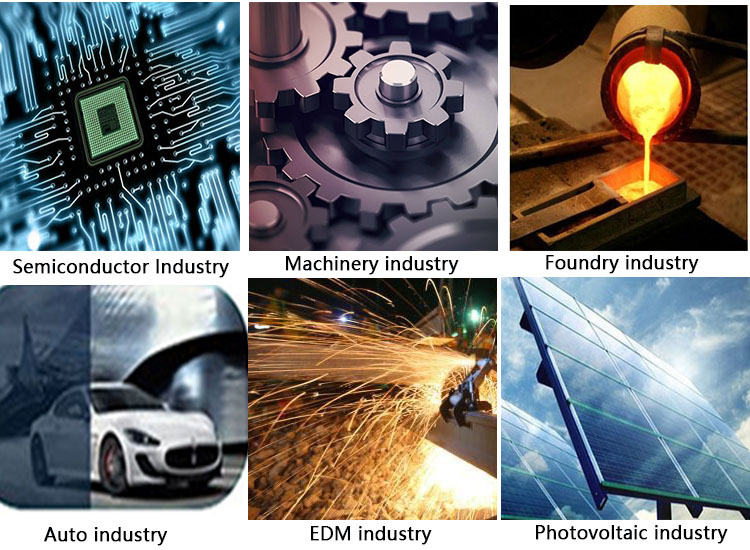

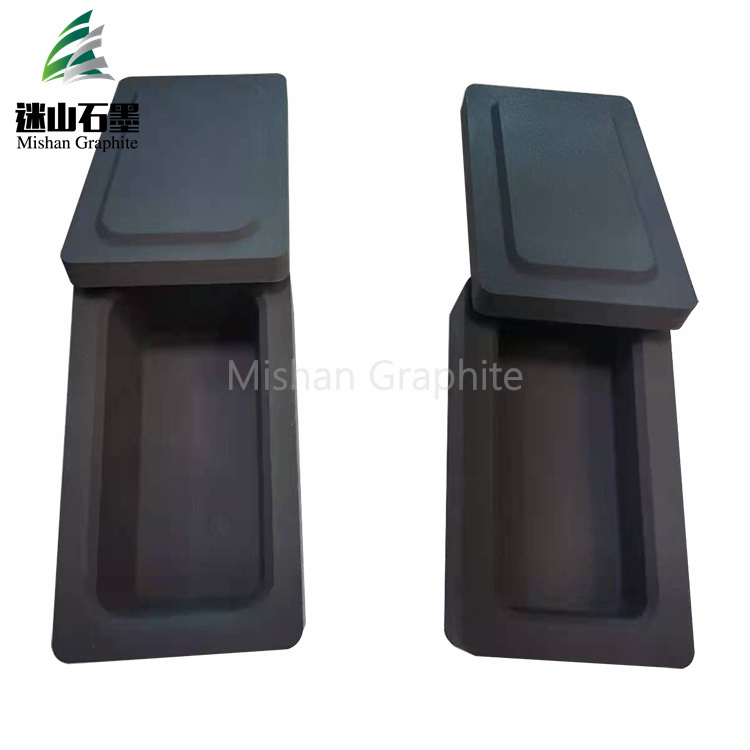

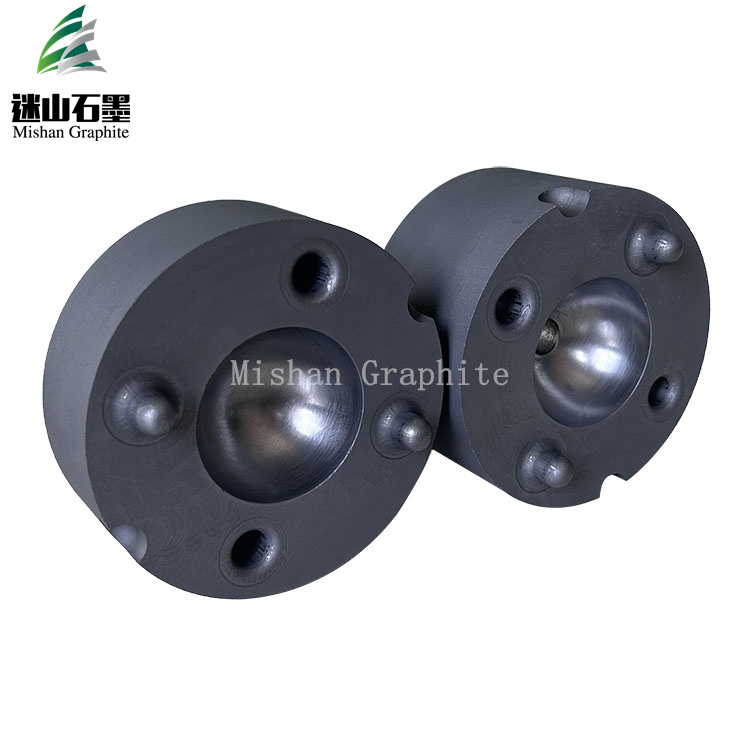

The use of graphite mould during the diamond saw blade tip manufacturing process is a key factor in maintaining consistency and accuracy in the final product. Graphite mould have high thermal stability, excellent electrical conductivity and resistance to thermal shock, which makes them ideal for the production of diamond saw blades.

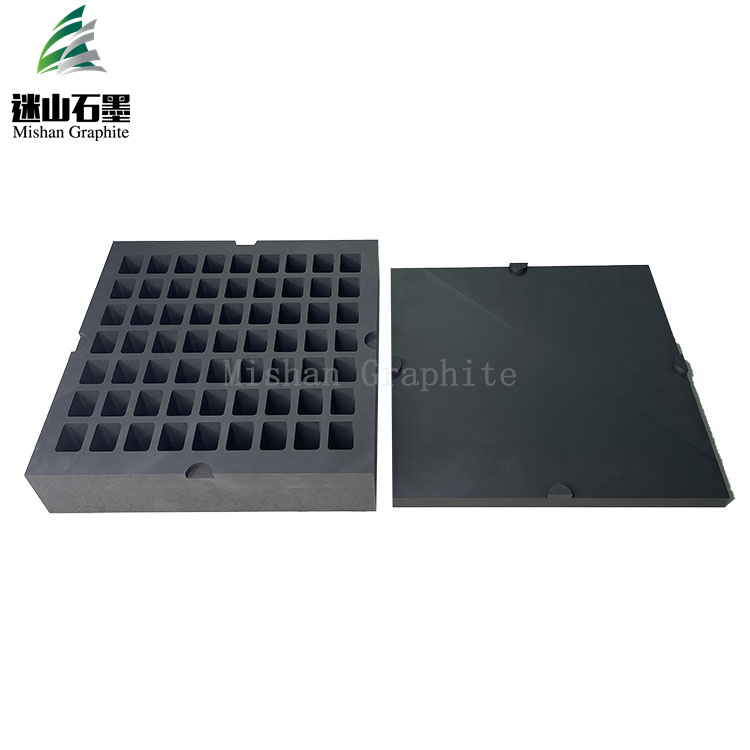

The manufacture of diamond saw blade heads begins with the design of the mold. The mold is then made using high quality graphite and precision machined to meet the required specifications. Once the mold is complete, the diamond powder is mixed with other additives to form the composite material for the segment.

The composite material is then poured into a graphite mould and subjected to high temperature and pressure conditions to ensure proper solidification and bonding of the diamond particles. Once the curing process is complete, the parts are removed from the mold, finished and mounted onto the blade. The result is an efficient, precise diamond saw blade that cuts hard materials with ease.

Diamond saw blade tip graphite mould help ensure the production of high quality diamond saw blades. Consistent and precise production of diamond saw blade tips is critical to the performance of the saw blade and the overall efficiency of the cutting process. Graphite mould provide a reliable and cost-effective solution for consistent and precise diamond saw blade tip production.

In short, the diamond saw blade graphite mould is a basic component in the diamond saw blade manufacturing process. The use of high-quality graphite mould ensures the consistency and accuracy of diamond saw blade tip production, thereby ultimately producing efficient and precise diamond saw blades.

Veneer cases or wooden cases or according to customers’ requirement.

3-20 days after confirming order,detail delivery date should be decided according to

production season and order quantity.