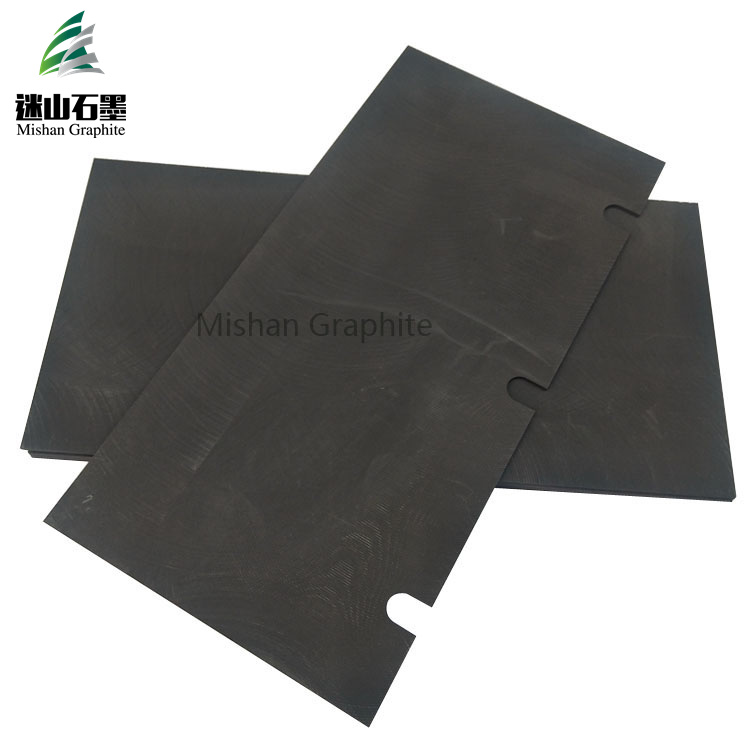

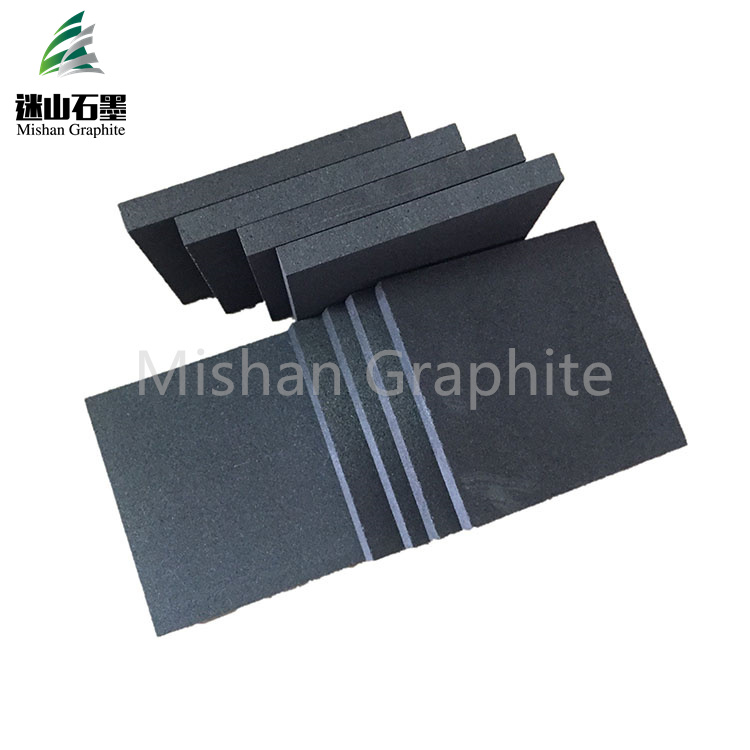

High electrical conductivity graphite plate

What are the properties of high electrical conductive graphite plate? High electrical conductivity graphite plate display excellent electrical conductivity due to their high purity and highly ...

Description

What are the properties of high electrical conductive graphite plate? PACKAGE: DELIVERY TIME:

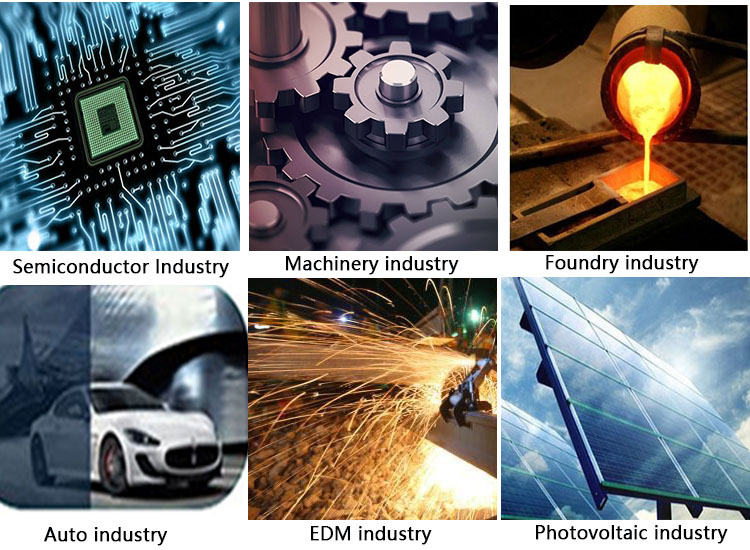

High electrical conductivity graphite plate display excellent electrical conductivity due to their high purity and highly crystalline nature. These characteristics make it an important material for various applications such as electronics, electrical, and mechanical industries.

What are the characteristics of high electrical conductivity graphite plate?

1. Its low resistance conductive ability. This is due to the large number of free electrons present in the graphite lattice. These free electrons allow electricity to flow efficiently through the material, making it ideal for applications requiring high conductivity. Some of these applications include electronic components such as circuit boards, switches, and sensors.

2. It is able to withstand high temperatures without losing its strength and mechanical properties. This makes it the material of choice in high-temperature environments where other materials cannot be used. Due to its excellent thermal conductivity, graphite plates are often used in radiators and cooling systems.

3. In addition to its electrical and thermal properties, high electrical conductivity graphite plate is also known for their chemical stability. They are resistant to most chemicals and can withstand harsh environments without corroding or degrading. This makes them ideal for use in chemical processing and other corrosive environments.

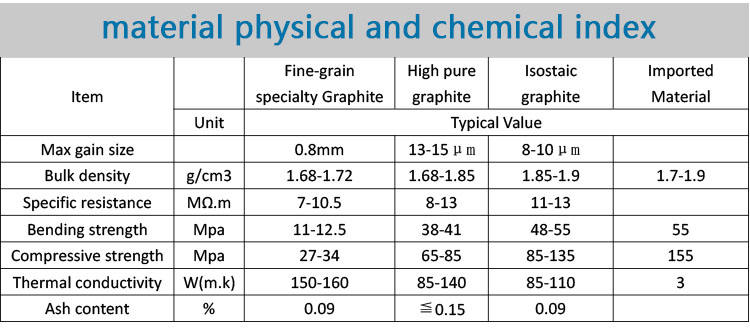

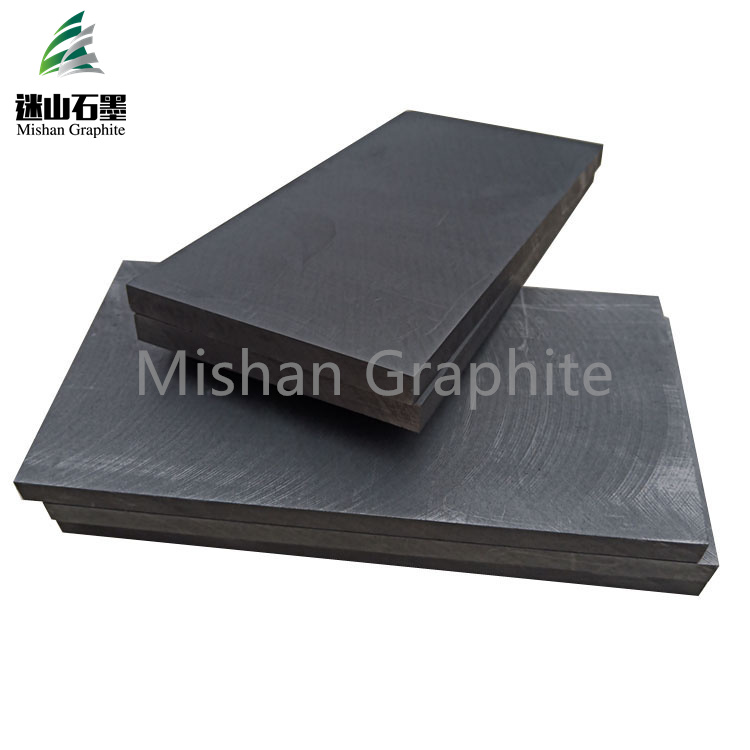

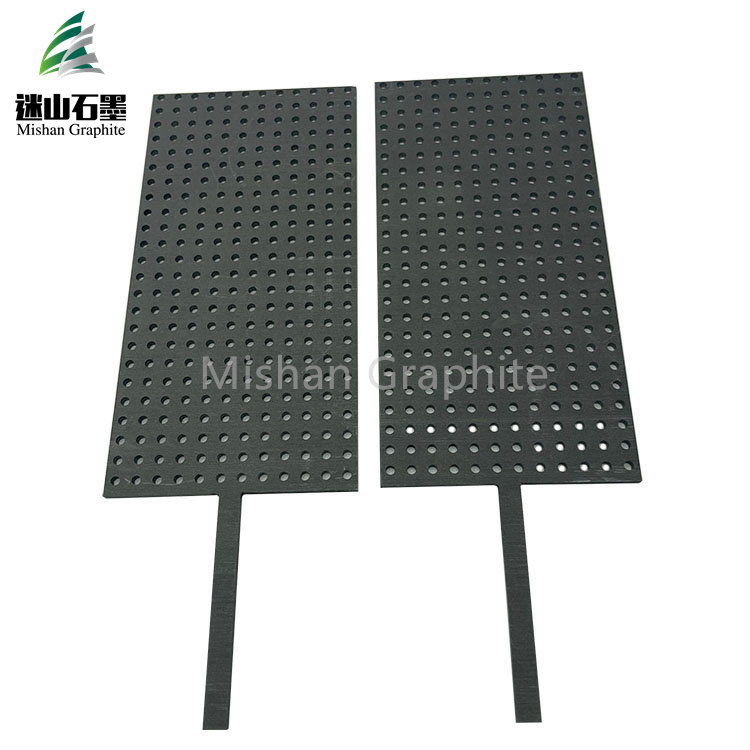

High electrical conductivity graphite plate is made of high-quality graphite material and are carefully selected and processed to ensure consistent and reliable performance. They are available in a variety of sizes, shapes and grades to meet the specific requirements of different applications. These boards can be machined, drilled and formed to meet the unique needs of each application.

Veneer cases or wooden cases or according to customers’ requirement.

3-20 days after confirming order,detail delivery date should be decided according to

production season and order quantity.