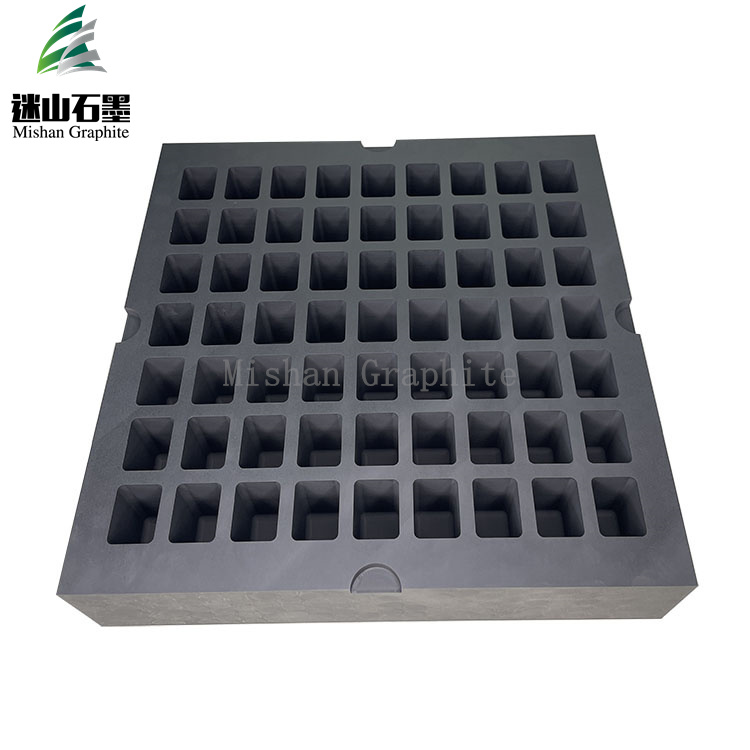

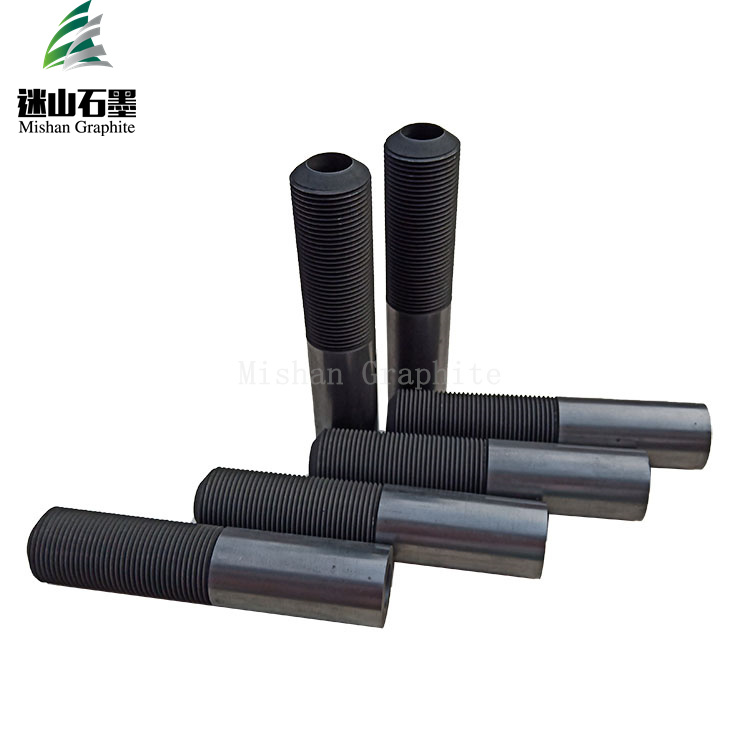

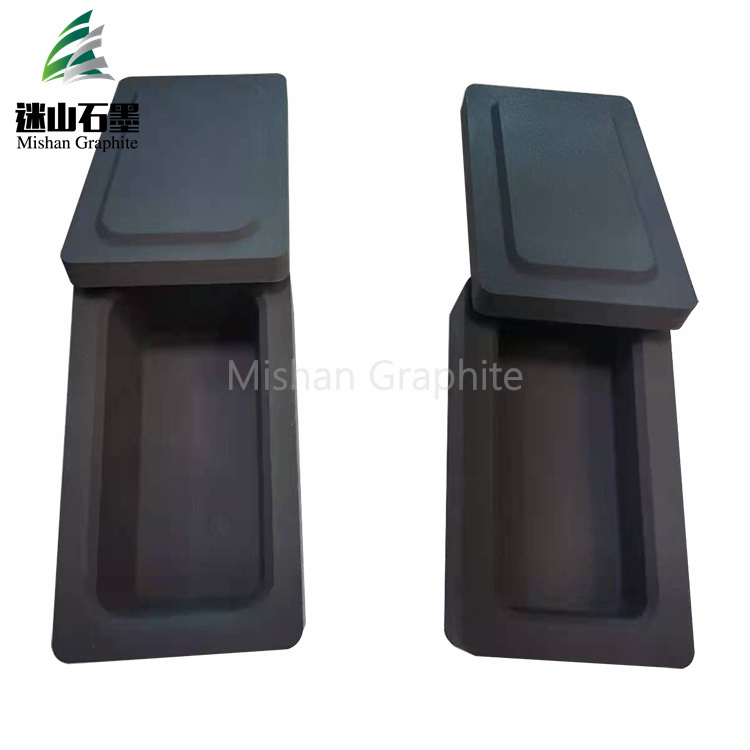

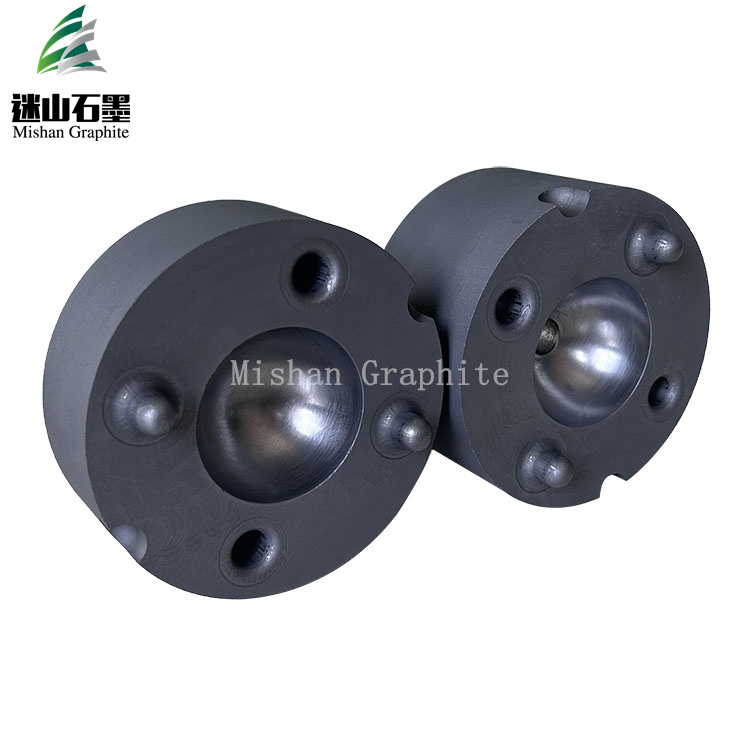

Graphite die mold for aluminum melting

Graphite die mold for aluminum melting have the characteristics of high thermal conductivity, excellent chemical resistance and low thermal expansion coefficient. Its use is extremely beneficia...

Description

Graphite die mold for aluminum melting have the characteristics of high thermal conductivity, excellent chemical resistance and low thermal expansion coefficient. Its use is extremely beneficial for the aluminum smelting industry. PACKAGE: DELIVERY TIME:

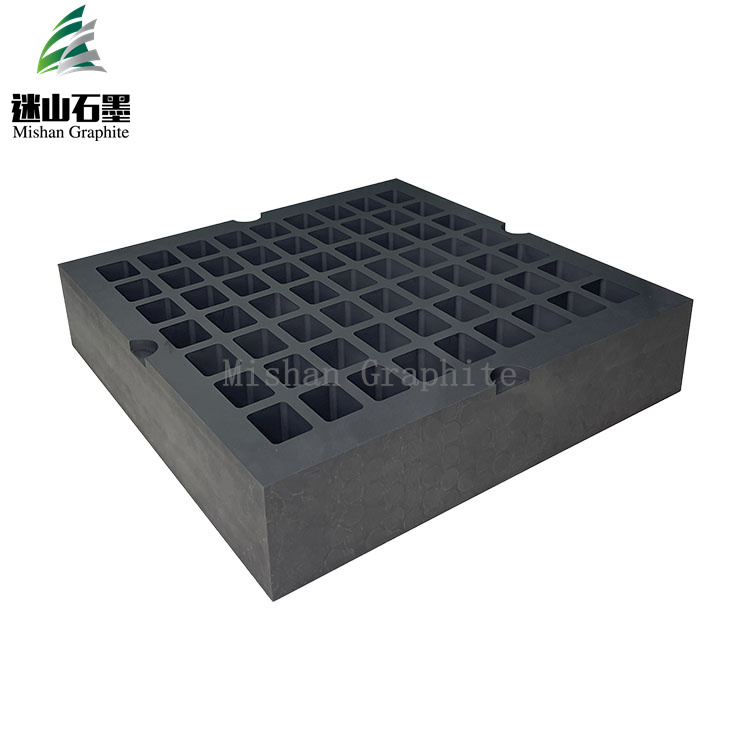

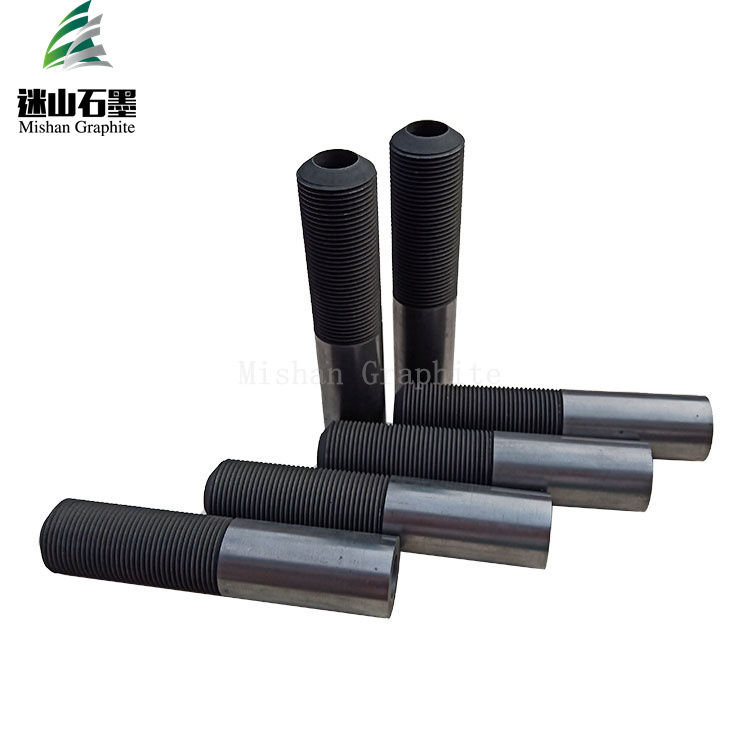

The reason why graphite molds can be used as tools for aluminum smelting is determined by their own characteristics:

1. High purity of graphite molds. The carbon content of graphite molds can reach 99%, and no unnecessary chemical reactions will occur during the aluminum smelting process, avoiding contamination of the metal and causing the quality of the casting to deteriorate.

2. Strength and toughness of graphite molds. This property allows graphite molds to withstand the high pressure and thermal stress imposed on them by molten metal during aluminum smelting.

3. Thermal shock resistance of graphite molds. This property allows graphite molds to withstand sudden and extreme temperature changes that occur during the process without cracking or deformation. Proper design and material selection help prevent molds from being damaged by thermal shock.

4. High thermal conductivity of graphite molds. This property allows graphite molds to effectively transfer heat from molten aluminum to the mold surface. This prevents the formation of hot spots, which can lead to premature mold failure and poor casting quality.

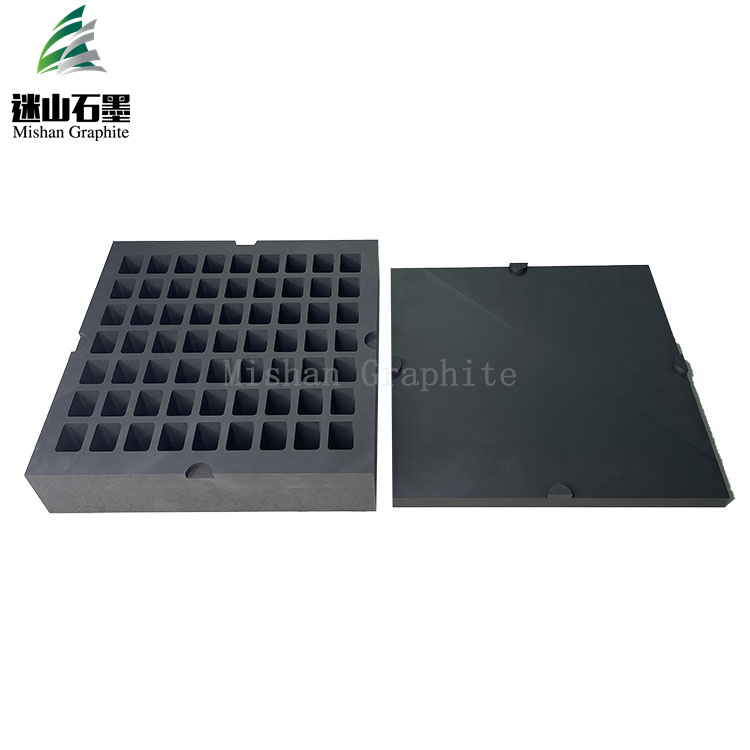

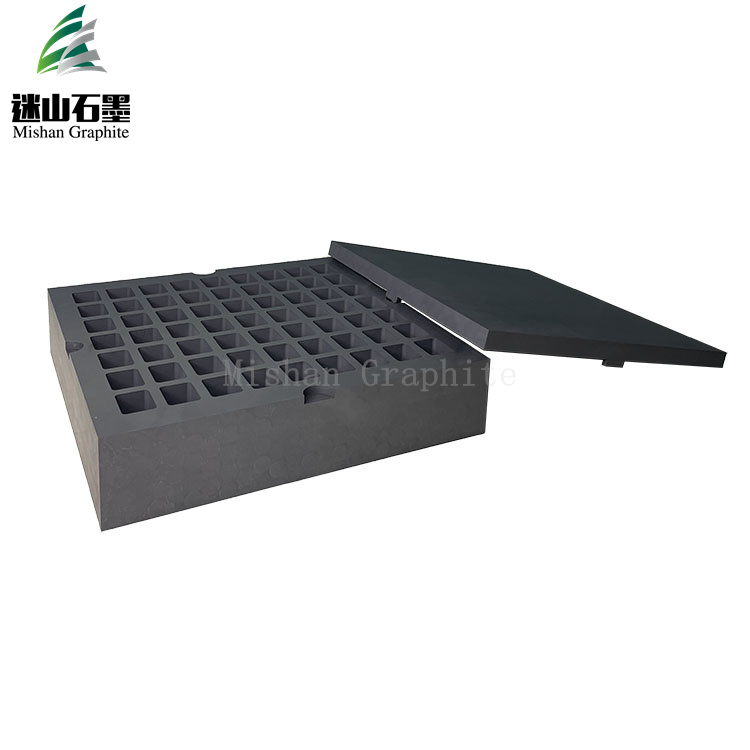

Veneer cases or wooden cases or according to customers’ requirement.

3-20 days after confirming order,detail delivery date should be decided according to

production season and order quantity.